Padlocks for Shipping Containers: A Complete UK Guide

Trying to secure a shipping container might seem straightforward on the surface, but picking the right padlock is a massive decision. It goes way beyond just grabbing the heaviest-looking lock off the shelf. Your average padlock, even a chunky one, is often no match for a determined thief who knows what they're doing. For real protection, you absolutely need a specialised padlock for shipping containers, built to withstand a serious attack.

Why Standard Padlocks Just Don't Cut It

You stare at the imposing steel doors of a container, and it's easy to think any old heavy-duty padlock from the local hardware shop will do the job. This is a common, and often very expensive, mistake. Using a standard padlock on a container is like using a bicycle lock to secure a bank vault—it gives you the illusion of security, not the real thing.

The biggest problem with a standard padlock is its exposed shackle. That U-shaped loop of metal is a sitting duck for bolt cutters, angle grinders, and pry bars, which are the go-to tools for everyone from opportunistic thieves to organised criminals. More often than not, it can be snapped or cut in a matter of seconds, giving them instant access.

The True Cost of Skimping on Security

Here in the UK, cargo theft is a relentless and costly headache, and using the wrong kind of padlock is a major reason containers get hit. A security audit of a major shipping firm back in 2019 revealed a startling fact: nearly 50% of container thefts were directly linked to weak or poorly chosen padlocks. That single statistic really drives home how vital the right lock is for protecting your assets.

But a break-in costs you more than just the value of your stolen goods. Businesses also have to deal with:

- Financial Losses: It's not just about the stolen cargo. You've also got the bill for repairing the damage to the container itself.

- Operational Delays: A compromised container can throw a huge spanner in the works of your supply chain, causing missed deadlines and even contractual penalties.

- Reputational Damage: When you fail to protect your client's goods, it erodes trust and can seriously harm your business's good name.

The goal isn't just to put off a casual thief; it's to defeat a determined one. A purpose-built container padlock, especially when paired with a protective lock box, shields the vulnerable shackle from attack. It presents a tough challenge that most criminals will simply decide isn't worth their time.

At the end of the day, investing in a high-quality padlock designed specifically for shipping containers is a critical business decision. It shifts your security from a simple deterrent to a robust, active defence. If this is all new to you, it’s well worth taking a look at the best lock solutions you've never heard of to get a better feel for the options out there.

Understanding Padlock Security Ratings and Materials

When it comes to picking the right padlock for your shipping container, you need to look beyond its size and weight. What really counts are the technical details that define its strength: the security ratings and the materials it’s made from. These two factors are what separate a real security device from something that’s just for show.

Without getting a handle on this, you're essentially just guessing which lock will actually protect what’s inside. The most dependable sign of a padlock’s toughness is its CEN (Central European Norm) rating, a standardised, independent grading system used right across Europe.

Here in the UK, it’s common practice to secure shipping containers with high-security padlocks that meet these tough standards. Certified locks are a familiar sight at UK ports and storage sites, helping to keep operations running smoothly by preventing theft and damage that cause expensive delays.

Decoding CEN Security Grades

Think of the CEN rating as a padlock's report card. It grades locks on a scale from 1 (lowest security) to 6 (highest security) based on how they hold up against a series of demanding tests. These tests aren't just theoretical; they mimic real-world attacks, including drilling, sawing, twisting, and pulling.

For securing a shipping container with anything valuable inside, you should only ever be looking at padlocks with a rating of CEN Grade 4 or higher. Honestly, anything less just isn't built to stop a determined thief with the right tools.

This table breaks down what each of the higher CEN grades really means in practical terms.

| CEN Grade | Resistance Level | Typical Attack Resistance | Recommended Use Case |

|---|---|---|---|

| CEN 4 | High Security | Resists attack from tools like saws, drills, and bolt cutters for a significant time. | The recommended minimum for most shipping containers. |

| CEN 5 | Extra High Security | Withstands prolonged attacks from heavy-duty power tools like angle grinders. | Containers in high-risk locations or holding very valuable goods. |

| CEN 6 | Maximum Security | Offers ultimate resistance against the most aggressive and sophisticated attacks. | Securing assets where a breach is absolutely not an option. |

As you can see, the grades give a clear picture of what you can expect. A Grade 4 is a solid starting point, but for higher-value contents or riskier areas, stepping up to a Grade 5 or 6 is a very wise move.

A CEN Grade 4 lock, like the Stronghold WS75 CEN 4 container lock, is the sweet spot for most container users. It provides excellent protection against common break-in tools.

Moving up to CEN Grade 5 gives you an even tougher defence, specifically designed to resist more sustained attacks from power tools. It’s a fantastic choice for containers holding high-value goods or sitting in less secure locations.

At the very top, CEN Grade 6 is the pinnacle of padlock security. These locks are engineered to offer maximum resistance against the most sophisticated attacks imaginable. This is for situations where security is non-negotiable.

Why Padlock Materials Matter

Beyond the official rating, the actual materials used to build the padlock are fundamental to its performance, especially when facing the unpredictable UK climate. A good lock has to be strong enough to resist brute force and durable enough to survive the elements without failing.

The best padlocks for shipping containers are usually made from specific metal alloys, each chosen for its unique strengths:

- Hardened Steel: This is the go-to choice for padlock bodies and shackles. It’s been heat-treated to make it incredibly tough and resistant to cutting and sawing.

- Boron Alloy Steel: A significant step up from standard hardened steel, boron alloys are exceptionally hard. This makes them a nightmare to cut, even with powerful bolt cutters and grinders.

- Stainless Steel: While not quite as hard as boron alloy, stainless steel’s main advantage is its superb corrosion resistance. This is vital for any padlock that will be exposed to salty sea air at ports or just general damp conditions, stopping it from seizing up over time.

Choosing the Right Type of Padlock for Your Container

Once you’ve got a handle on security ratings and materials, it’s time to move from theory to the real world. Picking the right type of padlock is a huge deal. The design of the lock is just as important as the metal it’s forged from, because different models offer unique advantages, especially when paired with a container lock box.

The main goal here is simple: protect the padlock’s most vulnerable part—the shackle. Two designs absolutely dominate the high-security scene for this very reason: shrouded shackle padlocks and disc padlocks. Both offer a serious defence against brute-force attacks from tools like bolt cutters and angle grinders, but they get the job done in slightly different ways.

Shrouded Shackle vs Disc Padlocks

A shrouded shackle padlock, sometimes called a closed-shackle lock, is designed with a body that extends upwards, wrapping around the shackle like a protective collar. This leaves only a tiny portion exposed, making it incredibly difficult for bolt cutters to get any grip. They’re a fantastic visual deterrent and offer beefy physical protection.

On the other hand, you have disc padlocks. Also known as shutter locks, these have a distinctive circular shape where the shackle barely peeks out from the body. Their compact, solid design leaves almost no shackle accessible, giving them exceptional resistance to cutting and prying. For a great example of this design in action, you can learn more about the versatile Quickfit Puck Lock and see how its form beefs up security.

The key takeaway is this: both designs aim to minimise shackle exposure. A shrouded lock builds a protective wall around the shackle, while a disc lock almost completely hides it within its circular steel body.

To help you choose the best lock for your container, here's a quick comparison of the most common high-security options.

Padlock Type Suitability for Shipping Containers

| Padlock Type | Key Advantage | Main Disadvantage | Best Paired With |

|---|---|---|---|

| Disc/Puck Lock | Minimal shackle exposure makes it extremely resistant to cutting. | Can be tricky to fit on some non-standard hasps. | A snug-fitting lock box for near-impenetrable security. |

| Shrouded Padlock | High shoulders protect the shackle from most bolt cutter angles. | Slightly more shackle is exposed compared to a disc lock. | Lock boxes that have enough vertical clearance. |

| Heavy-Duty Padlock | Widely available and fits most standard container hasps. | The exposed shackle is its most significant vulnerability. | A deep lock box that fully encases the lock body and shackle. |

Ultimately, either a disc lock or a shrouded padlock will serve you well, especially when protected by a lock box. The final choice often comes down to the specific dimensions of your container’s locking gear.

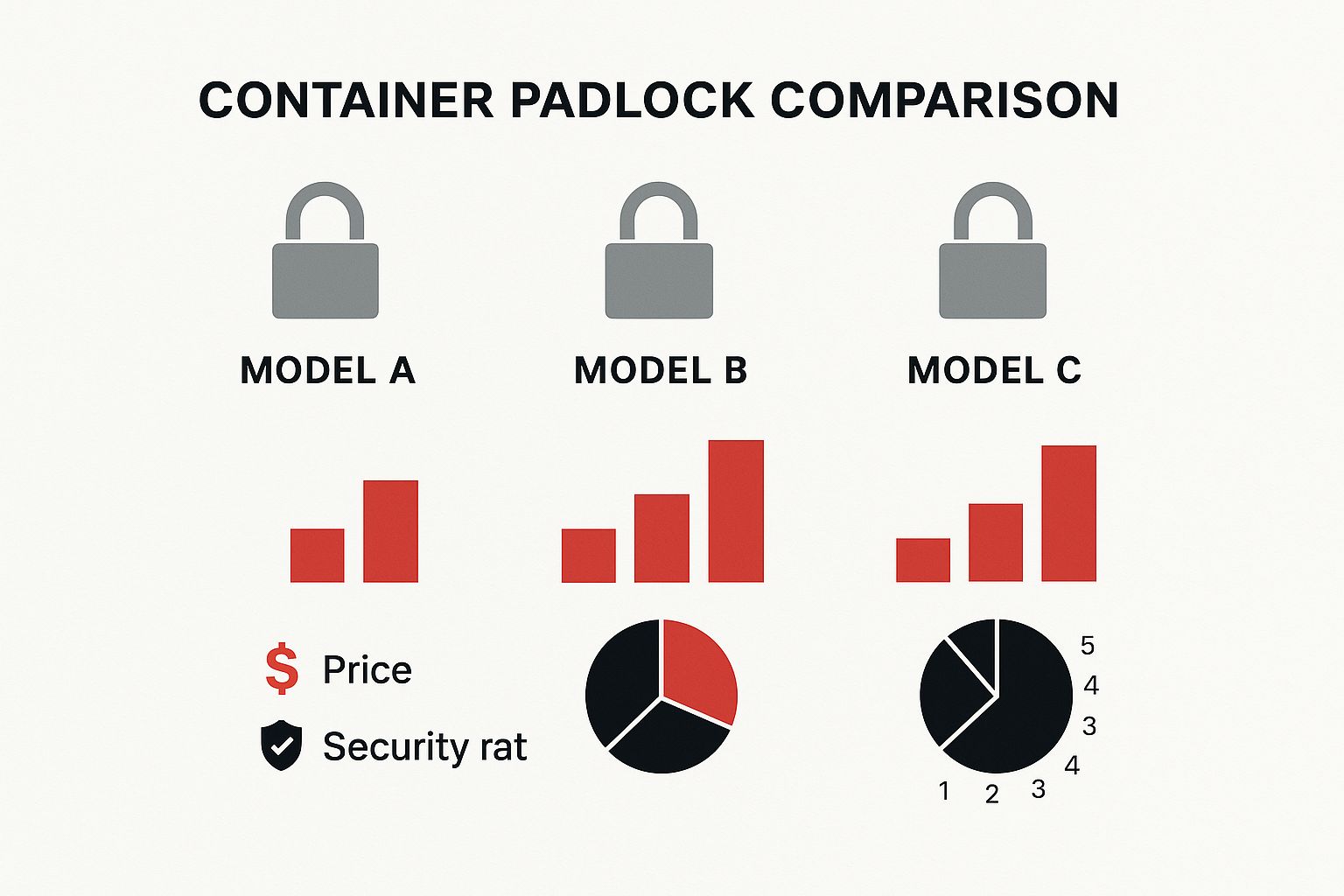

This chart gives you a general idea of how padlock price and security ratings relate to one another for common container lock types.

As the infographic makes clear, you get what you pay for. Higher security ratings almost always mean a higher price tag, which reflects the advanced engineering and tougher materials that have gone into the lock.

Ensuring a Perfect Fit with a Lock Box

Most modern shipping containers come fitted with a lock box—a thick steel housing welded onto the doors to shield the padlock. This is an absolutely essential security feature that works hand-in-hand with your lock. But here's the catch: an ill-fitting padlock completely defeats the purpose of the lock box, either by rattling around and creating a weak point or by being too big to fit at all.

To guarantee a secure, snug fit, you have to take some precise measurements before you even think about buying a padlock. Just follow these simple steps:

- Measure Internal Width: Grab a tape measure and find the inside width of the lock box. Your padlock's body must be narrower than this measurement to slide in.

- Measure Vertical Clearance: Check the height from the bottom of the lock box up to the hasp where the shackle will go. The entire padlock has to fit comfortably in this space.

- Check Shackle Diameter: Measure the diameter of the hole in your container's locking hasp. The padlock’s shackle needs to be thick enough for security but not so thick that it won't pass through the hole.

Taking these three quick measurements is a non-negotiable step. It’s the only way to be sure you’re choosing a padlock that will fit snugly inside its protective housing, truly maximising your container's security.

How Key Systems and Locking Mechanisms Work

Beyond the chunks of hardened steel and fancy security ratings, it’s the guts of a padlock that really count. The core and its key system are what stand between a thief's picking tools and your valuable gear. A top-tier padlock is only as good as its internal mechanism, so understanding how these systems work helps you find the sweet spot between day-to-day convenience and serious access control.

The first big decision is figuring out your keying system. This simply means deciding how many keys should open your padlock, or your whole fleet of them. It has a massive impact on both security and how easily your team can get their work done.

Keyed Different, Keyed Alike, and Master Keyed Systems

You’ve got three main options, and each one is built for a different job.

- Keyed Different (KD): This is the classic setup. Every padlock has its own unique key that won’t open any other lock. It’s the most secure option by a long shot because if one key goes missing, only a single container is at risk.

- Keyed Alike (KA): With this system, you can order a whole batch of padlocks that all open with the same key. This is a game-changer for convenience if you're managing multiple containers on one site. No more fumbling with a huge ring of keys; just one key to rule them all.

- Master Keyed (MK): This is the more sophisticated, layered approach you see in big organisations. Each padlock has its own key (just like a KD system), but there's also a special ‘master key’ that can open every single lock in the set. This lets managers have universal access while individual workers can only get into their assigned containers.

So, what's the catch? It all comes down to a trade-off. Keyed Alike is wonderfully convenient, but it also creates a single point of failure. If that one key is lost or stolen, your entire set of containers is suddenly wide open.

A padlock is a precision instrument. Its internal complexity is what separates a simple deterrent from a genuine security device. Understanding the difference between a pin-tumbler and a disc-detainer core is crucial to appreciating what you are really paying for.

Pin Tumbler vs Disc Detainer Mechanisms

The locking mechanism, or core, is the heart of the padlock. This is where the real fight against lock picking and bumping is won or lost.

The most common mechanism you'll find is the pin-tumbler lock. It works using a series of small pins of different lengths. The correct key lines these pins up perfectly, allowing the core to turn. They’re fine for general use, but a determined thief with the right tools can learn to manipulate these pins.

For high-stakes security, like protecting a shipping container, the disc-detainer mechanism is in another league entirely. Instead of pins that can be pushed up, it uses a set of rotating discs. The correct key has angled cuts that twist these discs into the right alignment, letting the lock open. This design is naturally far more resistant to picking because the discs give a thief’s tools no real feedback. They need rotational force, not just a simple lift, making them incredibly difficult to manipulate and offering a much higher level of protection against covert attacks.

Installation and Maintenance Best Practices

Choosing a top-tier padlock is a fantastic start, but even the toughest lock is only as good as its installation and upkeep. Securing a shipping container isn't a one-off job; it's a long-term commitment. A few simple practices will maximise your padlock’s lifespan and keep it a formidable defence for years to come.

First things first: a secure installation. A high-quality padlock performs best when it’s shielded from direct attack, and that's where a lock box comes in. The goal is to fit the padlock inside this steel housing so there’s virtually no room for tools like crowbars or bolt cutters to get a grip.

A snug fit is absolutely crucial. If the padlock is too small for the box, it can be rattled around and manipulated. Too large, and it won't fit at all. For a truly robust setup, a weld-on lock box creates a near-impenetrable shield around your padlock.

Protecting Your Padlock in the UK Climate

The UK's damp climate and salty coastal air are relentless enemies of metal. Rust and corrosion can seize up a padlock's internal mechanism, rendering it useless right when you need it most. For any padlock exposed to the elements on a shipping container, a simple maintenance routine isn't just a good idea—it's non-negotiable.

This proactive care stops the lock from jamming and ensures the key turns smoothly every single time. At the end of the day, a well-maintained lock is a reliable one.

Regular maintenance isn’t just about keeping a lock functional; it’s an essential security measure. A seized or corroded lock is a compromised lock, creating a vulnerability that is easily avoided with a few minutes of care.

A Simple Six-Month Maintenance Routine

Follow this straightforward process twice a year to keep your padlock in peak condition. If your lock is in an especially harsh environment, like a port or coastal area, you might want to do this every three to four months.

-

Thorough Cleaning: Start by blowing any loose dust and debris out of the keyway and drainage holes using compressed air. Then, grab a stiff brush to scrub off any surface grime or corrosion from the lock body and shackle.

-

Strategic Lubrication: Getting the lubricant right is vital. Avoid using oil-based products like WD-40, as they have a nasty habit of attracting grit and dust that will eventually clog up the internal mechanism.

Instead, go for one of these far superior alternatives:

- Graphite Lubricant: This is a dry powder that provides excellent, long-lasting lubrication without attracting dirt. It's an old-school solution that just works.

- PTFE Spray: A modern, synthetic, non-stick lubricant that actively repels water and prevents corrosion, making it perfect for the UK's wet weather.

Apply your chosen lubricant sparingly into the keyway and onto the shackle. Insert the key and turn it several times to work the lubricant deep into the locking mechanism, ensuring every moving part gets coated. Wipe away any excess, and your padlock is ready to face another six months of service.

Got Questions About Shipping Container Padlocks?

Choosing the right padlock for your shipping container means thinking about everything from security ratings to what it’s made of. To help you lock down your security strategy with confidence, we’ve put together answers to the questions we hear most often. This should clear up any last-minute doubts and make sure your gear is properly protected.

Even when you know the basics, a few practical questions always pop up before you buy. Let’s get them sorted.

What Is the Best Padlock for a Shipping Container in the UK?

There’s no single “best” lock that fits every single situation, but if you’re looking for a top-tier choice for typical UK conditions, you can’t go wrong with a closed-shackle padlock made from hardened boron steel. Make sure it has a CEN rating of 4 or higher. That combination gives you a seriously tough defence against the most common break-in methods.

If you’re worried about more sophisticated attacks, look for models with a disc-detainer locking mechanism. They are exceptionally difficult to pick.

But here’s the most important bit: compatibility. The best padlock on the planet is useless if it doesn't work with a proper container lock box. This steel housing is your ultimate defence against bolt cutters and angle grinders because it shields the lock from a direct assault.

Are All Shipping Container Locking Mechanisms the Same Size?

No, they aren’t, and this is a detail you absolutely have to get right. While most ISO shipping containers follow standardised designs for their locking gear, small differences from manufacturing or just general wear-and-tear can throw things off. You should always, always measure the inside of your container’s lock box or the locking rod handles before you buy a padlock.

There are two measurements you need to focus on:

- Shackle Diameter: This is how thick the U-shaped bar is. It needs to be slim enough to fit through the hasp's hole but chunky enough to be secure.

- Vertical Clearance: This is the distance from the bottom of the lock box up to the hasp. The body of your padlock has to fit comfortably in this space.

Getting these measurements right isn’t optional. A lock that’s too small for the box can be jiggled around, creating a weak spot. One that’s too big simply won’t fit at all.

How Often Should I Maintain My Container Padlock?

For any padlock that lives outside, especially in the UK's damp coastal or industrial areas, a bit of regular maintenance is vital for keeping it reliable. We recommend giving it a quick look-over every three months just to check for any obvious rust or damage.

A proper clean and lubrication should be done at least every six months. If you feel the key getting stiff or tricky to turn, don’t wait – do it sooner.

When you do lubricate it, use a graphite or PTFE-based spray. Oil-based products are a bad idea because they attract dust and grit, which will eventually gum up the works. A little bit of care prevents rust and makes sure the lock works smoothly when you need it to.

Can I Use Multiple Padlocks on One Container for Extra Security?

Yes, you absolutely can – and it's a brilliant security move. Most standard shipping containers have two vertical locking bars on the right-hand door. Sticking a high-quality padlock on each one is a fantastic deterrent. It immediately doubles the time and effort a thief would need to get inside.

Using two keyed-alike padlocks is a great way to add an extra layer of security. It forces an intruder to defeat two separate, tough locks just to get the doors open, which might be enough to convince them to find an easier target.

Just remember to focus on quality, not quantity. Two CEN 4-rated padlocks for shipping containers offer far more protection than four cheap, unrated ones. The goal is to create a real barrier, not just something that looks like one.

At Quickfit Container Accessories, we specialise in high-quality, durable security solutions built to handle the rough and tumble of shipping and storage. Take a look at our range of CEN-rated padlocks, lock boxes, and other essential gear to build a security system that truly protects what’s important.

Find the perfect security accessories for your container at Quickfit Container Accessories