A Guide to Seals for Containers

Don't think of a container seal as just another lock. It's more like a unique security signature for your cargo. In UK and international logistics, its role is vital. These seals are designed to provide indisputable evidence of tampering, much like the old wax seals on a confidential letter.

Why Container Seals Are Your First Line of Defence

A broken or missing seal is an immediate red flag. It instantly signals a potential security breach, protecting your goods from theft, contamination, and anyone trying to gain unauthorised access. It's the clearest and quickest sign that something has gone wrong somewhere between the point of origin and its final destination.

That simple piece of metal or plastic suddenly becomes a critical data point. For anyone involved in the supply chain, the integrity of that seal is paramount, carrying significant legal and financial weight.

The True Cost of a Compromised Shipment

When a seal is compromised, the fallout is far more than just the loss of goods. The consequences can ripple through a business, causing serious disruption and financial pain. You could be looking at:

- Financial Penalties: Hefty fines from customs authorities and a sharp increase in your insurance premiums.

- Legal Disputes: Costly legal battles with clients or partners over lost or damaged cargo.

- Reputational Damage: A loss of trust with your customers that can be incredibly difficult to rebuild.

This is exactly why choosing the right seal isn't just a routine operational task—it's a foundational business decision. To get a better handle on how crucial security measures like these are, it's worth exploring comprehensive transportation risk management strategies.

A Growing Market for Security

The growing importance of solid sealing solutions is easy to see in the market's growth. The global container seal market is already valued at over £2 billion and is projected to nearly double by 2033, thanks to rising trade volumes and ever-increasing security demands.

Here in the UK, major ports like Felixstowe and Southampton depend heavily on these seals to protect goods and stay compliant with international security protocols.

Choosing a container seal is not merely a logistical step; it's a commitment to cargo integrity. It tells your clients, customs officials, and partners that you take the security of the supply chain seriously.

Choosing the Right Type of Container Seal

Picking the right seal for your container isn't a one-size-fits-all job. Far from it. The best choice comes down to the journey your cargo is taking—what’s inside, where it's headed, and just how much security it needs. Not all seals offer the same level of protection, and matching the seal to the risk is a crucial step in keeping your supply chain secure.

Think of it like choosing a lock for your home. You wouldn't use a simple padlock for a bank vault, and you don’t need a complex alarm system for a garden shed. Container seals work on the same principle of appropriate security, falling into a few distinct categories built for specific jobs.

High-Security Barrier Seals

For any international shipment or cargo with a high price tag, high-security seals are the go-to standard. These aren't just flimsy indicators; they are tough physical barriers engineered to take a beating and stop determined thieves in their tracks.

-

Bolt Seals: These are the real workhorses of global logistics. Made of a solid steel pin and a locking mechanism, they can only be removed with a hefty pair of bolt cutters. Their main job is to provide serious physical strength and leave behind crystal-clear evidence of tampering, making them a must-have for customs compliance on international sea voyages.

-

Cable Seals: A bit more flexible than bolt seals, these use a high-tensile steel cable that you thread through locking points and pull tight. They’re perfect for securing containers with slightly misaligned doors or for things like tanker lorries and rail cars where a rigid bolt just won’t fit. Once that cable is cut, it frays, making it impossible to reseal—leaving obvious proof of a breach.

These barrier seals are your first line of defence for valuable goods travelling long distances, like a shipment of electronics from Asia to a distribution centre in Manchester or pharmaceuticals that need a secure cold chain.

Indicative Plastic Seals

On the other end of the spectrum, indicative seals serve a different, but just as important, role. Made from plastic, their primary function isn’t to put up a fight but to give you clear, instant visual proof if someone’s been messing with your cargo.

They are designed to be broken easily by hand or with a simple cutting tool, but doing so destroys them. Each one has a unique serial number that gets logged, creating a clear chain of custody. If your container shows up with a broken seal or a number that doesn't match the manifest, you know instantly it’s been opened.

An indicative seal is a bit like the security tape on a medicine bottle. It won’t stop you from opening it, but it provides undeniable proof if someone else has.

This makes them ideal for domestic haulage, like securing roll cages on a supermarket lorry or as a secondary check seal on a container inside a UK warehouse.

Comparing Common Container Seal Types

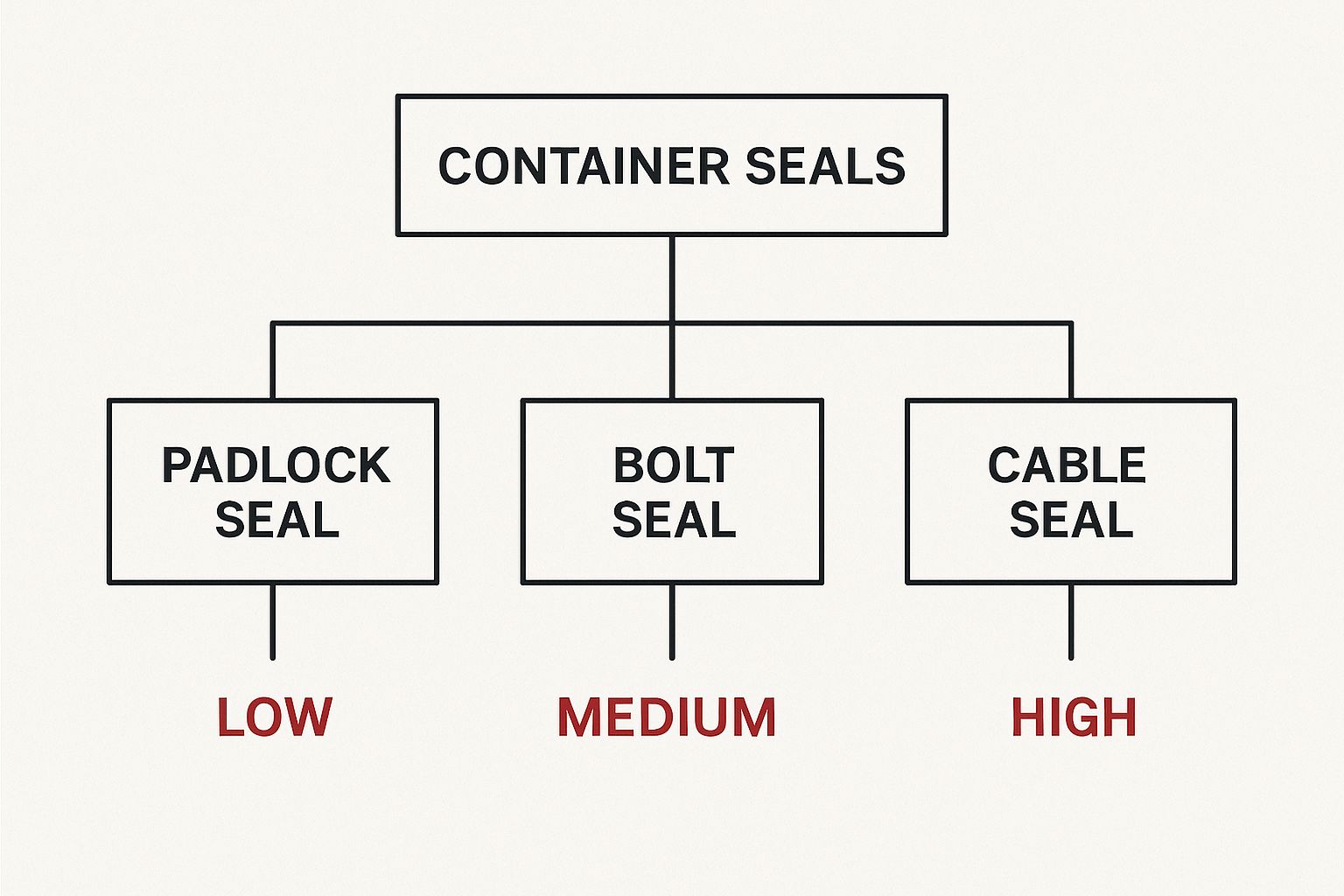

To help you visualise the differences, here’s a quick breakdown of the most common seal types, their security levels, and where you'll typically see them used.

| Seal Type | Security Level | Primary Material | Common UK Use Case |

|---|---|---|---|

| Bolt Seal | High | Steel | International shipping, high-value goods |

| Cable Seal | High | Steel Cable | Securing misaligned doors, tankers, rail cars |

| Indicative Seal | Low (Tamper-Evident) | Plastic | Domestic transport, internal logistics, roll cages |

Choosing between a high-security barrier and a simple indicative seal really depends on balancing the value of your cargo against the potential risks it faces on its journey.

The image below shows this security hierarchy clearly, illustrating how protection ramps up from a basic indicative seal to a robust bolt seal.

As you can see, the security level jumps significantly as you move up the scale. Getting these distinctions right is fundamental to making a smart choice. For a deeper dive, you can explore more expert advice on how to properly seal a container.

Understanding How Materials Impact Seal Strength

The real story of a container seal’s strength isn’t in its shape or colour—it’s in the materials it’s made from. What separates a seal that acts as a genuine barrier from one that’s just a visual deterrent is the science baked into its very core.

High-security bolt and cable seals are forged from high-tensile steel, and for good reason: sheer strength. This isn't your everyday steel; it's engineered to fight back against brute force attacks like cutting, pulling, and heavy impacts. Think of it as the difference between a simple garden gate latch and a bank vault door. One suggests you stay out, the other makes it a formidable challenge.

The Role of Polymers in Tamper Evidence

Indicative seals, on the other hand, play a completely different game. These are usually made from polymers like polypropylene or nylon, and their purpose isn't to resist force but to reveal it.

These plastics are designed to be tattletales. When someone tries to tamper with them, they break, stretch, or deform in a very obvious way, leaving undeniable proof of interference. This predictable failure isn't a bug; it's the most important feature.

The material science of a seal determines its security narrative. High-tensile steel is designed to shout "Stop!", while an indicative polymer is engineered to whisper "I've been touched". Both messages are vital for a secure supply chain.

Withstanding Environmental Challenges

Beyond fending off physical attacks, seal materials have to survive the journey. Many high-quality seals are coated to resist corrosion from relentless saltwater spray and to handle wild temperature swings. The materials used in both the seal and the container itself are crucial. For instance, when it comes to ensuring robust metal enclosures protection from heat and condensation, you quickly realise how every single component has to work in harmony.

This is especially critical for specialised cargo, like cold-chain logistics, where materials can't afford to become brittle in sub-zero temperatures. In the UK, the importance of polymers is clear even in the wider packaging market, where polypropylene sealing tapes command a huge 40.7% market share. It's all part of the same ecosystem focused on keeping goods secure.

Applying and Managing Seals for Maximum Security

A high-security seal is only as strong as the process behind it. Just locking a container isn't enough; real security comes from a strict, well-documented protocol that turns a simple component into a robust defence system. A disciplined approach ensures every seal delivers on its promise of integrity from origin to destination.

It all starts with the correct application. A seal that's poorly fastened is just a security risk waiting to happen, offering an easy opportunity for tampering. It’s vital to make sure the seal is properly engaged and pulled tight, leaving zero room for manipulation.

Building a Watertight Seal Management Protocol

Effective management isn't just a good idea—it's non-negotiable. It creates an unbroken chain of accountability that can be audited at every stage of the supply chain, making it far more difficult for security breaches to go unnoticed.

A robust protocol should always include these steps:

- Record Everything: The unique serial number on every seal must be meticulously recorded on all shipping documents, including the Bill of Lading. This number is the seal’s identity.

- Verify at Every Handover: At every point the container changes hands—from the warehouse to the haulier, at the port, and upon final delivery—the seal must be visually inspected. The physical seal must be checked against the number on the paperwork.

- Document the Check: Each inspection should be logged with a time, date, and signature. This creates a clear and traceable history, proving the seal was intact at specific points along its journey.

This systematic approach makes spotting discrepancies simple and immediate. For more guidance on reinforcing your defences, you can learn about essential container security practices that complement a strong seal protocol.

Responding to a Compromised Seal

Knowing what to do when something goes wrong is just as important as the preventative measures. A clear, pre-defined response plan is crucial for managing a potential breach effectively.

If a seal is found broken, missing, or with a number that doesn't match the documentation, treat it as a significant security incident until proven otherwise. The first step is not to open the container, but to document and report.

You need to establish a clear procedure for these events. This should involve immediately photographing the compromised seal and the container, notifying all relevant parties (shipper, carrier, and security personnel), and moving the container to a secure area for a formal inspection, ideally witnessed by an authorised official.

Meeting UK Standards and Embracing Future Technology

Staying ahead in the logistics game means knowing two things: the rules you have to follow today and the tech that's just around the corner. For any business operating in the UK, getting international standards right isn't just good practice—it's what keeps your cargo moving smoothly through customs and your supply chain secure.

The big one to know is ISO 17712. This is the international standard that classifies container seals based on their raw physical strength. To get an 'H' for high-security, a seal has to pass some pretty tough tests. This isn't just a suggestion; it's a requirement for most international shipments clearing UK ports. Using an ISO 17712-compliant seal tells customs authorities you've done your job securing your cargo against tampering.

The Rise of Smart Seals

While a tough physical seal is still the foundation of container security, the future is looking a lot more digital. We're now seeing the arrival of 'smart seals', and they're completely changing the game from a passive check to active, real-time monitoring.

Think about a seal that does more than just click shut. These next-generation electronic seals are a massive leap forward. They can:

- Pinpoint your container's exact location with real-time GPS tracking.

- Keep an eye on internal conditions, like temperature and humidity.

- Ping your phone with an instant alert if the seal is cut or even just messed with.

This technology flips the whole security model on its head. Instead of finding out about a break-in hours or even days later, you get a notification the second it happens. That allows for a much faster response.

Smart seals are turning containers from silent boxes into intelligent, communicative assets. This move towards active monitoring provides a level of supply chain visibility that was previously impossible.

This shift is part of a much bigger trend of technological growth in the UK's industrial sectors. The UK gasket and seals market, which container seals are a part of, is set to grow to £2.76 billion by 2032. This growth is being driven by tougher regulations and non-stop innovation, showing just how critical sealing solutions are becoming. You can read the full research on the UK gasket and seals market to get more insight into this expansion.

By getting a grip on today's standards while keeping an eye on tomorrow's tech, UK businesses can make sure their security measures are both compliant and ready for what's next. For a closer look at the different types available, you can browse a wide range of options for container security.

Frequently Asked Questions About Container Seals

To help you put all this information into practice, we’ve put together answers to some of the most common questions our customers ask about seals for containers. Think of this as a quick reference guide to clear up any lingering doubts and give you the confidence to manage your container security like a pro.

Getting the details right ensures your logistics operations are not just secure, but also fully compliant with industry standards. It's the best way to prevent costly delays and potential fines down the line.

What Is an ISO 17712 Compliant Seal and When Do I Need One?

An ISO 17712 compliant seal is the gold standard for container security. These are high-security seals, usually bolt or cable types, that have passed a battery of tough, independent tests for physical strength and tamper-evidence.

You’ll almost always need one for international maritime container shipments to comply with global security programmes like C-TPAT. It's always best practice to check the specific requirements for your shipping route and destination to make sure you’re fully compliant.

What Should I Do if a Container Arrives With a Broken Seal?

If a container shows up with a compromised seal—or a number that doesn't match the paperwork—your first move should be to not open it. The immediate priority is to secure the area and document everything meticulously.

Start by taking clear photos of the dodgy seal and the container number. Then, get on the phone straight away to the shipper, the carrier, and your own security team. The container should be moved to a secure inspection area, and ideally, only opened in the presence of a customs official or surveyor to formally investigate what's happened.

Can I Reuse a Container Seal?

Absolutely not. You must never, ever reuse a container seal. Every single security seal is specifically designed for one-time use to guarantee its integrity and provide reliable proof of tampering.

Once a seal is removed—which usually means destroying it with bolt cutters—its security features are gone for good. Using a new, uniquely numbered seal for every single shipment is a fundamental principle of maintaining a secure and trustworthy supply chain.

This practice is non-negotiable for ensuring a clear, unbroken chain of custody. If you're looking for other specific components, you might also find our guide to container door parts useful.

For all your container security needs, from high-security bolt seals to indicative plastic seals, Quickfit Container Accessories provides reliable solutions to keep your cargo safe. Explore our extensive range and secure your shipments today at https://www.quickfitcontaineraccessories.co.uk.