Your Guide to Shipping Container Cladding

Think of shipping container cladding like a high-performance jacket. On its own, a shipping container is a tough, industrial box. But when you want to live or work in it, that box needs an upgrade. Cladding is that essential outer layer that protects it from the elements, keeps it warm, and makes it look fantastic.

This ‘jacket’ is more than just about aesthetics; it’s a critical component for proper weatherproofing, insulation, and getting your project to meet UK building standards.

Why Cladding Is a Non-Negotiable Upgrade

At its heart, shipping container cladding is an external layer fixed to the outside of the original container walls. A standard container is built tough enough for life at sea, but that doesn't mean it’s ready for long-term use as a home or office in a typical residential or commercial setting. Cladding changes everything.

It provides a second skin that shields the container’s Corten steel from the UK’s famously damp climate. This is absolutely key to stopping rust in its tracks and massively extending the container's lifespan, making it a wise investment for any container project, from a simple garden office to a full-scale family home.

More Than Just a Pretty Face

The real magic of cladding is that its benefits go far beyond just looking good or stopping corrosion. This external layer is what truly transforms a basic steel box into a comfortable, compliant, and energy-efficient building.

Let's quickly summarise the core advantages.

Core Benefits of Container Cladding at a Glance

| Benefit | Brief Explanation |

|---|---|

| Thermal Performance | Creates a space for insulation, drastically improving heat retention and lowering energy bills. |

| Aesthetic Versatility | Lets you completely change the industrial look to match any style, from rustic timber to sleek metal. |

| Superior Weatherproofing | Forms a robust barrier against wind and rain, preventing leaks and protecting the container's structure. |

| Regulatory Compliance | Helps meet UK Building Regulations for fire safety and thermal efficiency (Part L), which is essential for habitable spaces. |

Essentially, when you add cladding, you're not just giving your container a facelift. You are fundamentally improving its performance and making it fit for purpose in the UK.

By adding an external layer, you are not just customising its appearance; you are fundamentally upgrading its performance, durability, and suitability for long-term use in the UK.

The demand for these kinds of projects is on the rise. With the global shipping container market valued at £6.6 billion in 2025 and the UK market set to grow at a CAGR of 2.1% through 2035, the need for quality shipping container cladding will only increase.

To see what's possible, it's worth checking out some innovative shipping container modular home projects. These real-world examples show perfectly how cladding is the final touch that turns a functional steel box into a genuinely desirable home or workspace.

Choosing Your Ideal Cladding Material

Picking the right material for your shipping container cladding is the most important decision you'll make. It dictates not just the final look, but also how the structure performs over time and, of course, the total cost. The 'jacket' you choose will determine whether your container melts into a rustic garden scene or stands out as a sharp, modern piece of architecture.

This isn't just about looks, though. It’s a very practical choice that directly impacts future maintenance, durability, and how well your insulation works. Let’s walk through the most popular options here in the UK to find the perfect match for your project.

Timber Cladding: Warmth and Natural Beauty

If you're aiming for a softer, more organic feel, you can't go wrong with timber. It’s the go-to choice for turning an industrial steel box into a cosy garden room, a welcoming office, or a home that feels like it truly belongs in its natural surroundings.

- Larch: Siberian Larch is a fantastic, cost-effective softwood. It’s packed with natural resin, which makes it impressively resistant to rot and decay right out of the box. Over time, it weathers beautifully to a distinguished silvery-grey.

- Cedar: As a premium option, Western Red Cedar is loved for its stunning reddish-brown colours and its remarkable stability and light weight. It needs very little upkeep and gives a sophisticated, high-end finish.

- Treated Softwoods: This is your most affordable entry into wood cladding. Woods like pine are pressure-treated with preservatives (you'll often hear it called 'tanalised' timber). They do need more regular maintenance to keep the weather at bay, but you can paint or stain them any colour you like.

There's just something about timber cladding. It has a natural appeal that completely softens the hard, industrial look of a container. It’s so versatile, letting you create anything from a rustic hideaway to a sleek, contemporary space, which is why it's a favourite for all sorts of projects.

Metal Cladding: Sleek and Industrial Finishes

Want to embrace the container's industrial roots or go for an ultra-modern, crisp aesthetic? Metal cladding is your answer. It's incredibly durable and provides clean lines that are perfect for pop-up shops, contemporary offices, or bold architectural designs.

Corten Steel is the iconic choice here. It’s famous for developing a stable, rust-like patina that actually protects the steel underneath, meaning it needs zero maintenance. For something lighter and more polished, aluminium panels are a brilliant rust-proof alternative. They come in a huge range of factory-applied colours and finishes. Exploring options from major suppliers, like those in guides such as the Top 7 Sandwich Panel Manufacturers in UAE, can also introduce you to clever insulated metal panel systems that are well worth a look.

Composite and Fibre Cement Cladding: Low-Maintenance Performers

For anyone whose top priorities are durability and minimal upkeep, man-made materials offer the best of both worlds. They give you the handsome appearance of natural materials but with far superior strength and weather resistance.

- Composite Cladding: Typically made from a blend of recycled wood fibres and plastics, composite boards simply don't rot, warp, or splinter. They are available in a vast array of colours and textures that often mimic real wood, but you'll never have to seal or stain them.

- Fibre Cement: This stuff is tough. Made from cement, sand, and cellulose fibres, it’s completely non-combustible, impervious to pests and rot, and holds paint for an incredibly long time.

Remember, the material you choose has a knock-on effect. The fixings for heavy fibre cement boards are very different from those for lightweight timber, and this can influence how you frame out openings. Our guide on installing shipping container windows has some great insights on how different cladding materials work alongside these crucial features.

Unpacking the Benefits of a Clad Container

So, you understand what cladding is, but what does it actually do for a shipping container? This is where things get interesting. Adding an external skin to a container isn't just about making it look pretty; it's a game-changer that boosts performance across the board. The real value lies in how it turns a standard steel box into a comfortable, efficient, and long-lasting building.

A well-installed cladding system gets to work straight away, tackling the natural weak points of a bare container. It’s what elevates the structure from a temporary fix to a genuinely high-quality space you’ll want to spend time in.

Superior Thermal and Acoustic Performance

One of the biggest wins is a massive improvement in thermal efficiency. The framework needed to hold the cladding creates a perfect space to pack in high-performance insulation. This simple addition makes a huge difference to heat loss, a crucial factor for anyone looking to keep energy bills down in the UK's climate. Your container will be warmer in winter and cooler in summer, making the inside environment far more stable and comfortable.

The same logic applies to sound. A bare metal container can be like living inside a drum, amplifying every drop of rain and gust of wind.

Cladding, especially when paired with insulation, is a fantastic acoustic buffer. It can transform a noisy, echoing box into a peaceful home office, a quiet garden studio, or a tranquil living space by deadening sounds from the outside world.

Unbeatable Durability and Longevity

Corten steel is tough, no doubt about it. But it's not indestructible, particularly when up against the relentless British damp. Cladding acts as a formidable first line of defence.

A properly designed system, which includes a ventilated air gap behind the panels, works like a protective rain jacket. It ensures any moisture that gets in can easily escape, preventing condensation from sitting against the steel walls. Managing this moisture is absolutely vital, and you can dive deeper into this in our article on shipping container vents. This proactive approach stops corrosion in its tracks, protecting your investment and the container's structural integrity for decades.

- Protective Barrier: The cladding shields the original steel from rain, harsh UV rays, and any accidental knocks or scrapes.

- Corrosion Prevention: It creates a breathable cavity, allowing the structure to dry out and halting the process that leads to rust.

- Increased Lifespan: By protecting the core structure from the elements, cladding can add many years to a container's working life.

Complete Aesthetic Transformation

Finally, let's not forget the most obvious benefit: shipping container cladding completely changes how it looks. You get total creative freedom, moving far beyond that utilitarian, industrial aesthetic. Want your container to blend into a rural garden? Go for natural timber. Need to make a bold architectural statement in a town? Sleek metal panels will do the trick.

This ability to customise the exterior is often key to satisfying planning permission requirements and achieving a finish that looks polished, intentional, and genuinely high-end.

Your Guide to Installing Container Cladding

Fitting shipping container cladding is a brilliant project for a keen DIYer, but it’s one of those jobs where getting the process right from the start is absolutely crucial. A top-notch installation all comes down to careful prep work and understanding the key stages, from getting the container surface ready to making sure the final finish is completely weatherproof.

Good planning and execution are what make the difference between a professional, long-lasting finish and a job that’s riddled with problems like dampness and a shoddy appearance. Think of it less like just sticking on pretty panels and more like building a robust, protective system for your container.

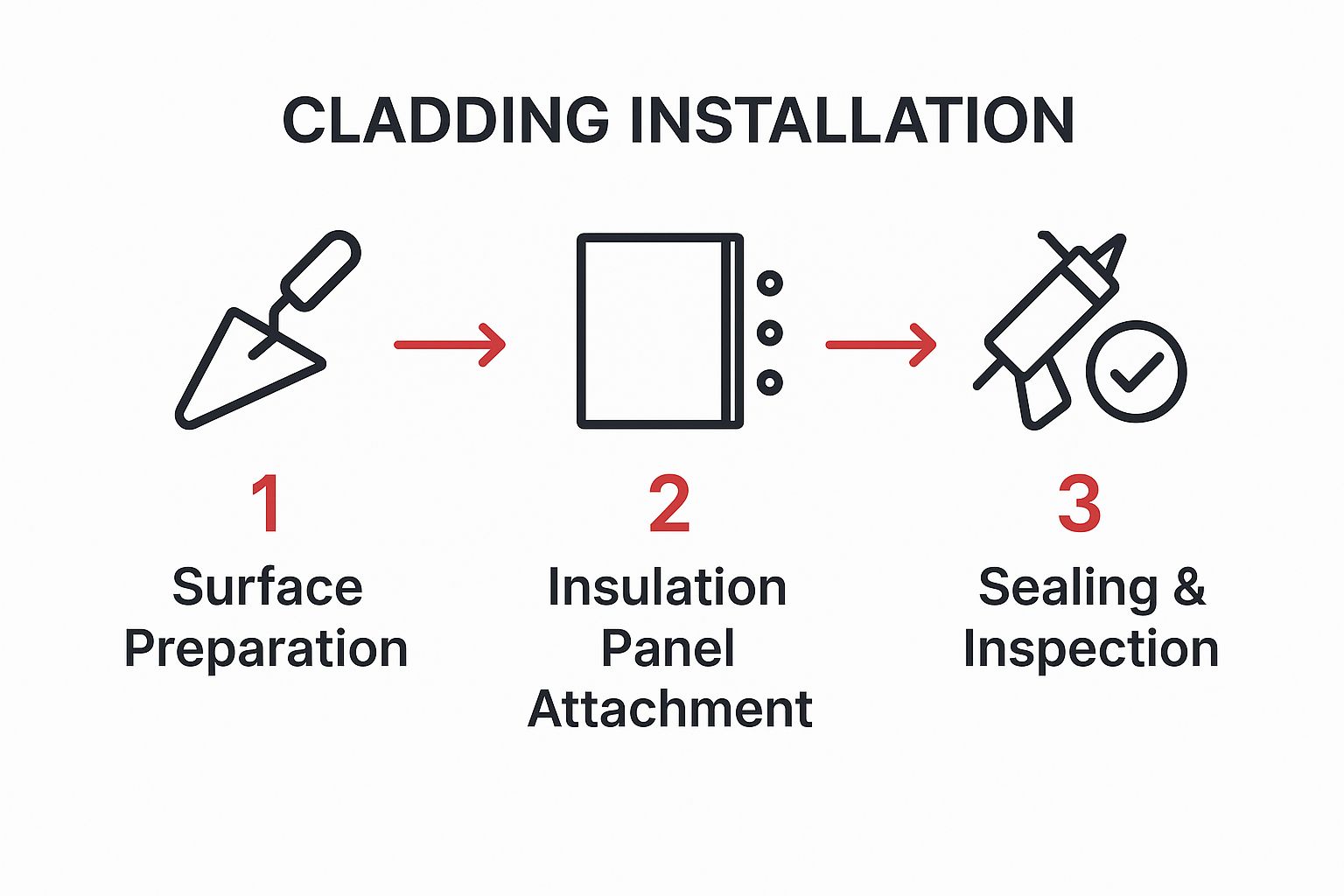

The whole process follows a fairly logical sequence. The image below breaks it down into three main stages to give you a clear picture of the journey from a bare metal box to a fully clad, stylish structure.

As you can see, the success of the whole project rests on that first preparation stage. Get that right, and you've got a solid foundation for attaching the frame and cladding, before sealing everything up. Cutting corners on any of these steps can undermine the whole thing.

Stage 1: Prepping the Surface

Before you even dream of attaching your first piece of cladding, the container itself needs to be spotless. This step is the bedrock of the entire project – it’s non-negotiable if you want the finish to last and to keep rust at bay.

First, give the container a really good wash down to get rid of any grime, grease, or salty residues from its life at sea. Next, you need to go over every inch of it, hunting for rust. Any corrosion you find has to be ground back to clean metal and treated with a quality rust converter or inhibitor. Once that's done, a coat of durable metal primer will seal the surface and get it ready.

Stage 2: Building the Support Framework

Here's something people often get wrong: you don't fix cladding directly onto the container's corrugated steel walls. Instead, you attach it to a support frame, which is usually built from pressure-treated timber battens fixed vertically to the container.

The most important job of this framework is to create a ventilated cavity—an air gap of at least 25mm between the container's wall and the back of the cladding. This gap is vital. It allows air to circulate, which stops moisture from building up and prevents condensation from getting trapped against the steel.

This framework also gives you a perfectly flat and true surface to fix the cladding panels to, which is key for getting that sharp, professional look. Make sure your battens are perfectly level and aligned before you even think about moving on.

Stage 3: Fixing and Finishing the Cladding

With the frame securely in place, you can finally start fixing your chosen cladding. How you do this depends on the material – timber boards are usually screwed on, while composite or metal panels might use special clips or fasteners.

- Cut with care: Take your time when cutting panels to fit around windows, doors, and other features. A neat, accurate cut is essential for both a clean look and a watertight seal.

- Fix it right: Always use the correct fixings for your cladding material. For timber, stainless steel screws are a great choice as they won't leave ugly rust streaks down the line.

- Weatherproof the details: The final, and arguably most critical, part is the finishing. You need to pay close attention to corners, joints, and any openings. Using the right trims and sealants is what creates a completely weatherproof shield. For a deeper dive, it's worth reading up on effective sealing solutions for containers.

While this is definitely a job you can do yourself, don't be afraid to call in a professional if you're feeling unsure about any stage, especially the structural framework or the tricky detailing. A bit of expert advice can save you from costly mistakes and guarantee your clad container is safe, durable, and looks fantastic.

Navigating UK Planning and Building Regulations

Before you get carried away with the exciting parts of your shipping container cladding project, there's a crucial step you absolutely cannot skip: the paperwork. Getting the legal side of things sorted in the UK can feel like a maze, but taking the time to understand the rules from the start will save you a world of headaches, money, and stress later on.

The two main hurdles you'll encounter are Planning Permission and Building Regulations. It's easy to mix them up, but they serve two very different purposes. Think of it this way: Planning Permission is about whether you can build something in a particular place and what it looks like, while Building Regulations are about how you build it to ensure it's safe and performs well.

When Do You Need Planning Permission?

Figuring out if you need planning permission hinges on the size of your container, its location, and how permanent you intend for it to be. A small container tucked away in a back garden for storage might slip through under ‘permitted development’ rights, but you should never just assume this is the case.

You will almost certainly need to apply for formal planning permission if your project involves any of the following:

- Habitable Use: Planning to use the container as an office, a garden room, or even a home? Permission is a must.

- Size and Position: Large containers, or any container placed close to your property boundary or in a very visible spot, will likely need the council's green light.

- Designated Areas: If you're in a Conservation Area, an Area of Outstanding Natural Beauty (AONB), or a National Park, expect much tighter rules and a definite need for planning permission.

Meeting UK Building Regulations

Even if your project is small enough to avoid the planning process, you'll still need to meet UK Building Regulations, especially if people will be inside it. This is where your choice of shipping container cladding becomes incredibly important.

The most critical rules are centred on fire safety. Your entire external wall system – the cladding, the insulation, and the frame it's attached to – must meet rigorous standards for fire resistance to stop flames from spreading.

Recent events have put building safety under a microscope, and for good reason. Government data from May 2023 revealed that over 5,000 high-rise residential buildings still had unsafe cladding, a stark reminder of why using compliant, fire-rated materials is non-negotiable for any structure, big or small.

Beyond fire safety, you'll also need to satisfy regulations for thermal efficiency (known as Part L) and structural safety. For a deeper dive into what this involves, a good starting point is understanding the costs associated with UK Building Regulations.

The best advice? Talk to your local council's building control department right at the beginning. They can give you clear, specific guidance for your exact project. For more tips on keeping your project safe, have a look at our guide here: https://www.quickfitcontaineraccessories.co.uk/blogs/health-and-safety.

Your Container Cladding Questions Answered

When you’re planning a container conversion, the cladding is a big decision that throws up a lot of questions. It’s a crucial step that defines the look and longevity of your project. Here, I'll walk you through the common queries we hear all the time, drawing on years of real-world experience to help you sidestep common mistakes.

Let's get straight to it.

What’s the Real Cost of Cladding a Shipping Container?

There’s no single price tag for this job. The cost to clad a shipping container here in the UK really depends on what material you fall in love with and whether you're brave enough to tackle the installation yourself. As a rough guide, you're looking at anywhere from £80 to £250 per square metre for materials and a professional fitting.

To put that into perspective, here’s how it usually breaks down:

- On a Tighter Budget (£80-£120/m²): Think treated softwood timbers or standard uPVC cladding. These options look fantastic and won't break the bank, but be prepared for a bit more upkeep down the road.

- The Sweet Spot (£120-£180/m²): This is where you find some of the most popular and reliable materials, like Siberian Larch, quality composite boards, and some fibre cement options. They hit that perfect balance between price, looks, and durability.

- The Premium End (£180-£250+/m²): If you’re after a truly show-stopping finish, you’ll be looking at materials like Western Red Cedar, rugged Corten steel, or sleek aluminium panel systems. They cost more upfront but deliver an incredible aesthetic and last a lifetime.

And don't forget the hidden costs! You'll need to budget for the timber battens that form the frame, insulation, all the necessary fixings, and any special trims to get that polished, professional look.

Can I Just Install the Cladding Myself?

Absolutely. If you’re a confident DIYer with the right tools, fitting your own shipping container cladding is a great way to save a significant chunk of money on labour. The job involves prepping the container, building a timber support frame (the battens), slotting in your insulation, and then carefully attaching the cladding itself.

But here’s the crucial bit most people get wrong: you must create a properly ventilated cavity behind the cladding. If you don't, you'll trap moisture against the steel, leading to condensation and, eventually, rust. It completely defeats one of the main purposes of cladding in the first place.

If you’re at all unsure about getting a perfectly watertight seal, especially around tricky areas like windows and doors, it’s honestly worth hiring a professional. A small leak from a shoddy installation can cause major headaches and expensive water damage later on.

What’s the Best Cladding to Stop Condensation?

This is a common misconception. No single cladding material, on its own, will stop condensation. The real secret is in the system you build behind it—one that focuses on proper insulation and, crucially, ventilation.

The best method by far is to create what's known in the trade as a 'warm wall' construction. This means fixing a continuous layer of rigid insulation board to the outside of the container, just before you install the timber battens for the cladding. This technique stops the cold outside air from ever touching the container’s steel walls, which kills the 'cold bridge' effect that causes condensation to form inside.

Combine that with a ventilated air gap between your insulation and the back of the cladding, and you’ve got a bulletproof system. Your container will stay warm, dry, and comfortable. So, whether you choose timber, metal, or composite cladding is less important for condensation than getting the behind-the-scenes setup right.

How Long Will My New Cladding Actually Last?

The lifespan of your cladding boils down to two things: the material you pick and how well you look after it.

- Treated Softwood: You can expect a good 10-15 years, but you'll need to re-stain or paint it every few years to keep it protected from the British weather.

- Hardwoods & Larch: Timbers like Siberian Larch or Cedar are naturally tough. They can easily last for 25-40+ years with very little fuss—often just a good clean.

- Composite & Fibre Cement: These materials are built for durability and often come with warranties of 25-50 years. All they really need is a wash now and then.

- Metal (Aluminium/Steel): A high-quality metal cladding system is a long-term investment that can look great for 40+ years or more.

At the end of the day, spending a bit more on a quality material and ensuring it’s installed correctly will give you a finish that not only looks stunning but also protects your container for decades.

For all the essential components to customise and maintain your shipping container, from ventilation to security, visit Quickfit Container Accessories. We provide high-quality, reliable parts with next-day UK delivery available. Find everything you need at https://www.quickfitcontaineraccessories.co.uk.