Doors for Shipping Containers A UK Conversion Guide

Picking the right door for your shipping container conversion is a bigger deal than you might think. It’s what stands between your stuff and the outside world, affecting everything from security and easy access to the overall feel of your space. While those original, beefy cargo doors are fantastic for security, they're often a nightmare for daily use. This is where a bit of customisation makes all the difference, letting you fit a door that actually works for your project.

Choosing the Right Door for Your Container Project

So, you’re turning a steel box into something useful—a workshop, a pop-up shop, or maybe a garden office. The first thing you'll run into is the door situation. Those original cargo doors? Built like a tank, but wrestling with them every day gets old, fast.

The demand for container conversions is on the rise. With the UK shipping container market projected to grow at a compound annual rate of around 2.1% through 2035, more and more people are facing this exact decision. This growth, tracked by firms like Future Market Insights, shows just how popular these projects have become for both business and personal use. That means you're not alone in figuring out which door will best serve your new space.

Key Factors to Consider

Before you start browsing catalogues, you need to get clear on what you actually need. How you plan to use the container is the single biggest factor that will steer your decision. For example, a container holding valuable tools needs a high-security steel door, no question. But a garden office? You’ll probably want something with glass to let the light in.

Here’s what you need to be thinking about:

- Security Needs: How much protection do your contents really need? A simple shed for garden tools won't demand the same Fort Knox treatment as a unit packed with expensive equipment.

- Frequency of Access: Are you in and out all day? If so, a simple personnel door is going to make your life a lot easier than battling with heavy cargo doors every time.

- Aesthetics and Functionality: Think about how the door will look and function. A roller shutter is perfect for a retail unit that needs a wide, welcoming opening, whereas a UPVC door can give a container office a more familiar, residential feel.

- Weatherproofing and Insulation: Here in the UK, keeping the weather out is a must. Whatever door you choose, make sure it has decent weather seals. If you're creating a space for people, good insulation is just as important to keep the temperature stable and comfortable.

Exploring Different Container Door Options

Once you realise the standard, cumbersome cargo doors just won't cut it for daily use, a whole new world of custom doors for your shipping container project opens up. The choice you make here will literally define how you interact with your container, turning it from a simple steel box into a genuinely functional and accessible space. From secure personnel doors to wide-opening shutters, each option strikes a different balance between convenience, security, and aesthetics.

The decision really boils down to what you're using the container for. For a simple workshop or a secure storage unit, a steel personnel door is a popular and seriously practical choice. It gives you a straightforward, secure way in without wrestling with the original heavy doors, making it perfect for frequent access.

Steel and UPVC Personnel Doors

Personnel doors are by far the most common modification, and for good reason. They are basically standard-sized doors designed to be fitted into the container's corrugated side walls, offering a familiar and easy way to get in and out.

-

Steel Personnel Doors: These are the go-to for anyone focused on security. Typically built from galvanised steel and featuring multi-point locking systems, they are a formidable deterrent against anyone trying to get in who shouldn't be. They're perfect for storing valuable equipment or for use on industrial sites.

-

UPVC Doors: If your container conversion is more of a habitable space, like a garden office or a studio, a UPVC door can be a great shout. It provides a more residential feel, often includes double-glazing to let in natural light, and offers better thermal insulation than its steel counterpart. The trade-off? It's generally less secure than a high-quality steel door.

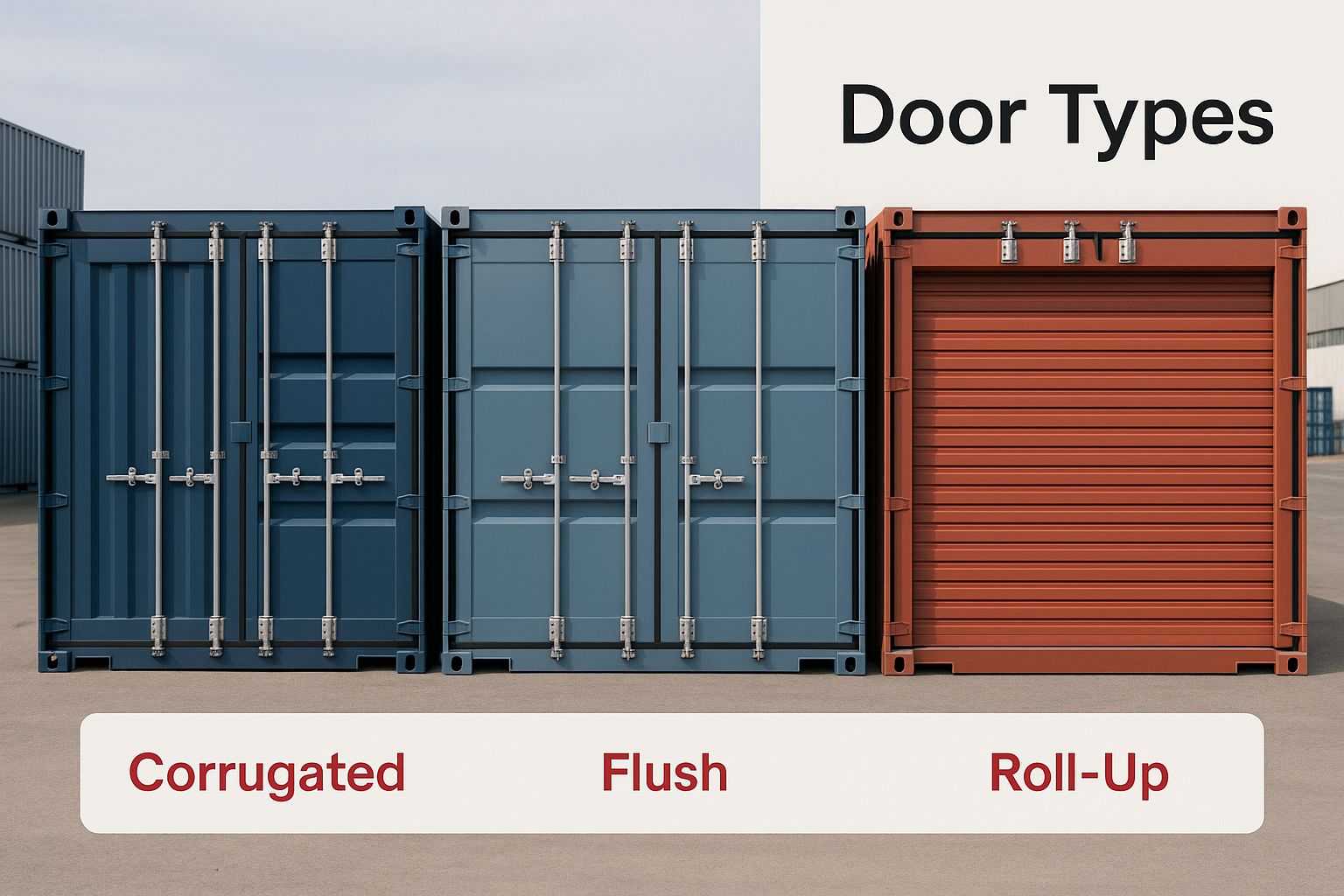

This image shows some of the most popular door types available for container customisation.

As you can see, each door style brings something different to the table, from the brute security of steel to the wide-open access of a roller shutter.

Roller Shutters and Glazed Doors

For projects that demand wider access or have a more commercial vibe, other options start to look much more appealing. Roller shutters, for instance, are a complete game-changer for pop-up shops, cafés, or workshops where you need to open up an entire side of the container.

Choosing the right door is about more than just access; it's about shaping the entire function of your container. A roller shutter transforms it into a storefront, while a glazed door turns it into a bright, inviting room.

Let's look at these alternatives for more specialised uses:

-

Roller Shutter Doors: Available in manual or electric versions, these doors can span a significant width. They are ideal for creating a servery hatch or allowing easy loading and unloading of bulky items with a forklift.

-

Glazed and Bi-Fold Doors: To truly maximise natural light and create a seamless indoor-outdoor flow, glazed doors are unbeatable. Patio sliders or bi-fold doors can transform a dark, imposing container into a stunning garden room or office, completely changing its character. They merge security with style, though you can expect high-quality units to come with a premium price tag.

Understanding Door Materials and Construction

Not all shipping container doors are made the same. Far from it. While two doors might look similar at first glance, what’s going on beneath the surface—the materials, thickness, and how they’re put together—is what really determines their security, how long they'll last, and how they’ll stand up to the relentless British weather. Getting this right is the difference between a door that serves you for years and one that fails after the first winter.

The material you choose is the first big decision, and it directly impacts both security and how well your container holds its temperature. For most projects, steel is the undisputed champion. Its sheer strength and durability make it the go-to for anyone serious about security.

Core Materials: Steel vs. Aluminium and UPVC

Galvanised steel is the industry standard for a reason. When you install a personnel door, you're cutting a hole into the container, and that's an open invitation for rust. The galvanisation process coats the steel in zinc, giving it a tough, protective shield against corrosion—an absolute must. The thickness of that steel, known as its gauge, is also a massive factor for security. Remember this: a lower gauge number means thicker, stronger steel, which is much harder for anyone to force their way through.

While steel is king for security, other materials have their place:

- Aluminium: It's lighter than steel and naturally rust-proof, which is why you often see it used for roller shutter doors. It offers a decent balance of strength and weight but won't give you the same brute-force protection as a heavy-gauge steel door.

- UPVC (Unplasticised Polyvinyl Chloride): If you're building a garden office or a studio, you'll probably run into UPVC. Its real strength is thermal insulation. A UPVC door with a double-glazed window will slash heat loss compared to a solid steel door, but it's generally seen as the least secure option of the three.

The Importance of Seals and Insulation

A door is only as good as the seal around it. Without proper weather stripping, you’re leaving your container wide open to wind, rain, and draughts. That leads to water damage and a space that’s miserable to be in. High-quality doors will have beefy rubber gaskets that create a tight, compressed seal when closed, stopping water from getting in and heat from getting out.

A poorly sealed door can undermine your entire container conversion. It's the difference between a dry, comfortable workspace and a damp, draughty box that's expensive to heat.

If you plan on actually spending time in the container, an insulated core is non-negotiable. Many steel doors are filled with high-density polyurethane foam, which works as a fantastic thermal barrier. This insulation helps keep the temperature inside stable—warmer in winter, cooler in summer—which can seriously cut down your heating and cooling bills over time.

It's a good idea to check your door's weather seals as part of your regular maintenance. If they look worn or damaged, you can find replacements like shipping container door gasket seals to keep your unit completely watertight.

How to Properly Secure Your Container Doors

For many, the real value of a shipping container lies in its brute strength and security. But let's be honest, the door is almost always the weakest link in the chain. Turning your container into a proper fortress requires a smart, layered approach to security, tackling the vulnerabilities of both the original cargo doors and any new personnel doors you might have installed.

The original heavy-duty cargo doors are exceptionally tough, but their locking mechanism is often the prime target for thieves. A simple padlock just won’t cut it. The first and most effective upgrade is to add a steel lockbox (sometimes called a shroud). This is essentially a thick steel box welded over the padlock area, making it virtually impossible for thieves to get at the lock with bolt cutters or grinders.

When you pair a lockbox with a high-security, heavy-duty padlock, you create a seriously formidable barrier. It’s a straightforward, cost-effective modification that dramatically beefs up the security of standard container doors.

Securing Aftermarket Personnel and Roller Doors

The moment you add a personnel or roller door, you introduce a whole new set of security considerations. While incredibly convenient, these doors can be a weak point if you don't choose them carefully. For maximum protection, you need to look for doors with advanced, built-in security features designed to shut down common break-in methods.

Consider these essential features for any new doors:

- Multi-Point Locking Systems: Instead of a single latch, these systems drive several bolts into the frame at different points—top, bottom, and side. This distributes any force applied and makes the door far more resistant to being prised open.

- Anti-Jemmy Bars: Also known as hinge bolts, these are fixed steel studs on the hinge side of the door. When the door closes, they slot into the frame. This means that even if a thief cuts the hinges clean off, the door still can't be removed.

- Internally Reinforced Frames: A strong door is useless without a strong frame. Look for doors with frames that are internally reinforced with steel. This provides a solid anchor and prevents the frame itself from being bent or twisted during an attack.

Peace of mind comes from layering security. A strong lock, a reinforced door, and a protected frame work together to create a system where the whole is much stronger than the sum of its parts.

A Layered Approach for Complete Protection

No single security measure is foolproof. The most effective strategy involves layering different security elements to create multiple obstacles for any potential intruder. This is especially important when you stop to consider the value of what's inside.

In the UK, containers are increasingly being used for high-value conversions like pop-up shops and modular housing. Protecting that investment is crucial.

Combining a high-security door with visible deterrents like CCTV and security lighting creates a powerful defence. For an even deeper dive into specific hardware and techniques, you can explore further advice on enhancing your shipping container security. This holistic view ensures all potential weak spots are covered, safeguarding your assets as effectively as possible.

Key Steps for Installation and Maintenance

Even the most bulletproof door is only as good as its installation. Fitting a new personnel door isn't just a matter of cutting a hole in your container; it's a structural change that can weaken the entire unit if you get it wrong. Nailing the installation and keeping up with maintenance is the only way to guarantee security, smooth operation, and a long life for your door.

A shipping container gets its incredible strength from its corrugated steel walls. The moment you cut an opening for a door, you interrupt that structure. That’s why it’s absolutely essential to weld a steel box frame into the aperture before you even think about hanging the door. This frame isn’t just a mounting surface—it’s a critical reinforcement that restores the wall's integrity, stopping it from flexing and keeping the container rigid. Skipping this step is asking for trouble.

DIY vs Professional Installation

One of the first decisions you'll face is whether to install the door yourself or call in a professional fabricator. Going the DIY route can definitely save you some cash, but it’s not a job for a beginner. You’ll need to be confident with measuring, cutting steel with a grinder or plasma cutter, and, most importantly, welding. A bad fit, a weak weld, or a misaligned frame will leave you with an insecure door that leaks.

A professional fabricator, however, brings experience and the right kit to the job. They’ll ensure the frame is perfectly square, the welds are strong, and the door hangs just right for a perfect, weatherproof seal. For most people, the extra cost is a small price to pay for the peace of mind that comes with a job done safely and correctly.

Think of the welded frame as the new backbone for that section of the wall. Without it, the door becomes a weak point, not just for security, but for the container's entire structure.

Essential Maintenance Checklist

Once your door is in, a little bit of regular TLC will keep it working perfectly and stop problems from developing. A simple maintenance routine doesn't take much time but can massively extend the life of your door and save you from expensive repairs later on.

Here are a few key things to do periodically:

- Lubricate Moving Parts: At least twice a year, apply a quality grease or lubricating spray to the hinges and locking mechanisms. This stops squeaking, cuts down on wear and tear, and keeps everything moving smoothly.

- Inspect Weather Seals: Take a look at the rubber gaskets around the door frame. If you see any signs of cracking, splitting, or perishing, replace them straight away. A damaged seal is an open invitation for water and draughts.

- Treat Cut Edges: The second you cut into a container, you expose raw steel to the elements. Make sure all cut edges are treated with a high-quality, rust-inhibiting metal primer and then painted over. Touch up any scratches or chips as soon as you spot them to stop rust in its tracks.

For a more in-depth look, check out this complete checklist for container door maintenance to ensure you've got all the bases covered. This proactive approach will keep your investment secure and functional for years to come.

Customisation and Aesthetic Upgrades

A door for your shipping container doesn't have to be just a functional entry point. Far from it. It can be the central design feature that sets the entire tone for your project, transforming a simple steel box into a real statement piece. When you move beyond pure utility, customisation lets you align the container's look with a specific brand, home design, or architectural vision.

One of the most powerful upgrades you can make is introducing natural light. Adding glazed panels or full windows to your doors can instantly make the interior feel more spacious and welcoming. This simple change is a complete game-changer for conversions like garden offices, studios, or pop-up shops. If you're thinking along these lines, our guide on fitting shipping container windows has plenty of practical advice on how to get it done.

Elevating Style with Finishes and Hardware

Aesthetic control goes way beyond just adding glass. With some thoughtful choices in finishes and hardware, you can elevate the look from purely industrial to something far more intentional and polished.

- Custom Paint Finishes: A professional paint job can either blend the door seamlessly with the rest of the container or create a bold, contrasting focal point. The key is to use high-quality, weather-resistant paint for a finish that’s both durable and stylish.

- Stylish Hardware Upgrades: It’s amazing what a difference the small details make. Swapping standard handles and locks for more design-led options in materials like brushed steel or matt black adds a real touch of sophistication.

- Smart Lock Integration: For a modern, keyless solution, integrating smart locks offers both convenience and a sleek, contemporary aesthetic. This is perfect for offices or accommodation projects where fiddling with keys is a hassle you can do without.

Integrating Modern Technology

The push for smarter, more efficient containers is definitely growing. Across the UK, we're seeing more technological advancements like IoT-enabled containers and enhanced tracking to improve supply chain transparency and cut down on losses. These innovations, combined with a drive for sustainability, are set to fuel market growth well past 2025. You can read more about these shipping container market trends if you want to dive deeper.

By thoughtfully combining colour, light, and modern hardware, you can turn a purely functional door into the architectural highlight of your container conversion.

Whether you're creating a chic retail space, a bespoke home, or an inspiring garden office, these customisation options prove that a container door can be both secure and seriously stylish.

Frequently Asked Questions

When you start planning a container modification, a few practical questions about adding new doors always pop up. Here are some straightforward answers to the queries we hear most often from our customers.

Can I Fit a Standard House Door on a Shipping Container?

While it might sound like a simple fix, trying to fit a standard residential door is a bad idea without some serious fabrication work. The corrugated steel walls of a container need a custom-welded steel box frame installed first.

This frame is essential. It gives you a flat, stable surface to mount the door, but more importantly, it restores the structural integrity you lose when you cut a hole in the container wall. Skip this step, and you’re asking for trouble with security, weatherproofing, and the container’s overall strength.

How Much Does Adding a Door Cost in the UK?

The price really depends on the type of door you choose and whether you get it professionally fitted. A basic steel personnel door kit will usually set you back somewhere between £250 and £500.

However, if you're looking at a high-security model or a big roller shutter door, the cost can easily jump past £1,000. Getting a professional to cut the opening and weld in the reinforcing frame will typically add a few hundred pounds on top of that.

Do I Need to Treat the Cut Steel Edges?

Yes, absolutely. This is a step you can't afford to skip if you want your container to last. When you cut into the Corten steel wall, you expose raw metal to the elements, making it a prime target for rust.

After cutting, the edges need to be ground smooth and immediately treated with a good quality, rust-inhibiting metal primer. Follow that up with a durable topcoat to seal the steel completely. This protective layer is what stops corrosion from taking hold and weakening the area around your new door.

For a comprehensive selection of high-quality doors, security accessories, and all the essential fittings for your container project, explore the extensive range at Quickfit Container Accessories. Visit our website for reliable solutions and next-day UK delivery. https://www.quickfitcontaineraccessories.co.uk