Unlocking Potential With Essential Container Accessories

A shipping container is a blank canvas. But with the right container accessories, you can transform it from a simple steel box into a genuine, high-value asset. Think of a standard container like a brand-new smartphone straight out of the box; the accessories are the apps you add to make it do exactly what you need, whether that's for storage, a workshop, or even a living space.

Unlocking Your Container's Full Potential

On its own, a bare container gives you secure, weatherproof space. That's a great start, but its real potential is only unlocked through customisation. A few smart additions can turn it into a secure workshop, a climate-controlled archive, or a functional on-site office. The trick is to figure out which accessories solve which problems before they become a headache.

Investing in the right add-ons from the start saves a massive amount of time, money, and frustration down the line. It’s the difference between a container that just about does the job and one that works perfectly for you.

The Growing Need for Customisation

The demand for versatile, modified containers is exploding. Just look at the UK's modular container market—its rapid growth is fuelling a massive need for specialised fittings. This market pulled in £2.16 billion in 2023 and is expected to hit £4.92 billion by 2030. That’s a serious annual growth rate.

This boom directly translates to more demand for accessories like intermodal twistlocks, corner protectors, and internal shelving—all crucial components for modular builds. You can dig deeper into the UK modular container market stats over at Grand View Research.

This guide will walk you through the core categories of customisation, giving you the knowledge to make smart decisions. We'll explore how to get your container kitted out for its specific role, covering key areas like:

- Security: Going beyond a simple padlock to integrated, high-strength solutions.

- Ventilation: Keeping the air fresh and stopping condensation damage in its tracks.

- Access: Adding doors, windows, and ramps to make your container easy and practical to use.

- Organisation: Making the most of every square inch with shelving and partitions.

By getting a handle on these fundamentals, you can make sure your container is perfectly equipped from day one.

Exploring Core Container Accessory Categories

Think of a bare shipping container as an empty house. It's got the basic structure, but it’s the furniture, the wiring, and the windows that make it liveable and functional. The same goes for containers. Choosing the right container accessories is how you move beyond a simple steel box and unlock its real potential.

These add-ons fall into a few key categories, with each one designed to solve a specific problem, from stopping thieves in their tracks to preventing internal climate issues. Getting your head around these categories makes it much easier to prioritise what you actually need. A container's job—whether it's for secure self-storage, a busy site office, or a mobile workshop—will always dictate which accessories deliver the most bang for your buck.

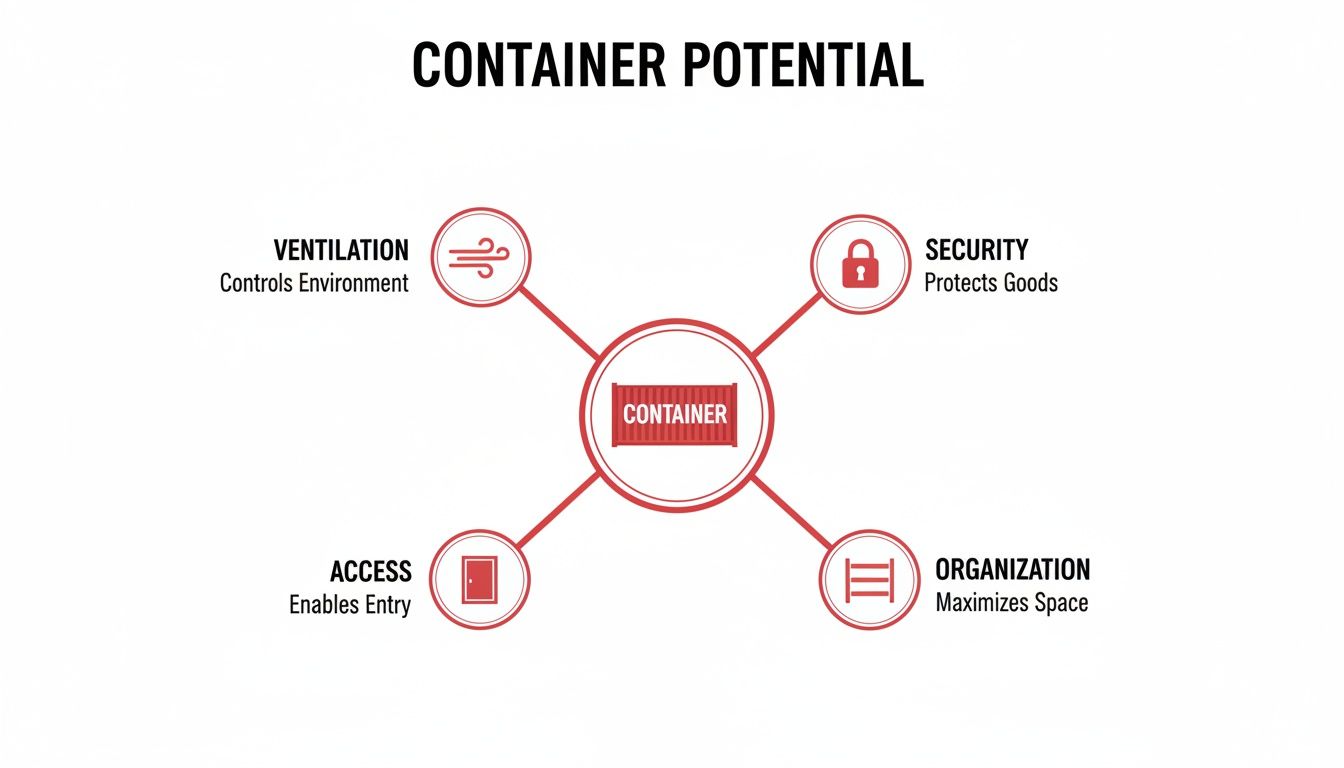

This diagram breaks down the four fundamental areas where accessories can completely transform a standard unit into something far more useful.

As you can see, a container's potential really opens up when you focus on security, ventilation, access, and organisation. Each of these is a key area for customisation.

Before we dive into the specifics, here's a quick overview of the main accessory types and the common headaches they solve.

Overview of Essential Container Accessory Types

| Accessory Category | Primary Function | Common Problem Solved |

|---|---|---|

| Security | Fortify entry points and deter unauthorised access. | Theft of valuable tools, equipment, or inventory. |

| Ventilation & Condensation | Control internal climate and prevent moisture damage. | 'Container rain', mould, rust, and damaged goods. |

| Access & Entry | Create user-friendly entry points for people and equipment. | Impractical heavy cargo doors for daily foot traffic. |

| Organisation & Storage | Maximise internal space and improve usability. | Cluttered, chaotic interiors and wasted vertical space. |

| Lighting | Illuminate the interior for safety and productivity. | Poor visibility, trip hazards, and inefficient working. |

| Seals & Gaskets | Ensure the container remains watertight and pest-proof. | Leaks, draughts, and infestations damaging contents. |

This table gives you a bird's-eye view, but the real value is in understanding how these solutions work on the ground. Let's get into the details.

Fortifying Your Container Security

Standard container doors are tough, no doubt about it. But their locking mechanisms can be a surprising weak point. Just slapping a padlock on isn't going to cut it if you're storing anything valuable. Real security is about creating layers of defence that both deter thieves and physically stop them from getting in.

High-security lockboxes are the foundation of any solid container defence. These are essentially thick steel shrouds welded or bolted over the padlock area. They make it almost impossible for bolt cutters or angle grinders to get a grip on the lock itself, acting as a powerful visual deterrent and a physical barrier.

Beyond that, tamper-evident seals offer a cheap and effective way to know if your container has been opened, either in transit or while left unattended on-site. They aren't a physical lock, but for logistics and tracking the chain of custody, they provide invaluable peace of mind.

Mastering Climate And Condensation Control

A sealed steel box is basically an oven in the summer and a fridge in the winter. These extreme temperature swings lead to a seriously destructive problem known as 'container rain'. As the air inside heats and cools throughout the day, moisture condenses on the cold ceiling and walls, dripping down onto your goods. The result? Rust, mould, and ruined stock.

A container without ventilation is like a room with no windows; it quickly becomes stale and damp. Installing vents gives the container a respiratory system, allowing it to breathe and equalise with the outside air, drastically reducing the risk of condensation.

A proper ventilation system is non-negotiable. Some of the most common options include:

- Static Vents: Simple, cost-effective louvred vents that allow for passive airflow, helping to release trapped, moist air.

- Whirlybirds (Turbine Vents): These wind-powered vents actively suck air out of the container, creating more consistent circulation even on still, humid days.

For the ultimate protection against drips, a specialised anti-condensation coating like Grafotherm can be applied to the interior ceiling. This fleece-like paint actually absorbs moisture as it forms and then releases it back into the air as vapour when conditions improve. It effectively stops drips before they even have a chance to start.

Creating Seamless Access And Entry Points

A container's original heavy cargo doors are brilliant for loading pallets with a forklift, but they’re a real pain for daily foot traffic. Modifying a container with dedicated access points makes it infinitely more user-friendly, turning it from a simple storage box into a functional workspace.

Installing a personnel door provides quick and easy entry without having to wrestle with the cumbersome main doors. It’s an absolute must-have for site offices, workshops, or any container you need to pop in and out of frequently. Adding windows is another great move—they bring in natural light, improve air circulation, and make the whole space feel less like a dark cave.

And for loading anything with wheels, from heavy equipment to tool carts, container ramps are indispensable. They create a smooth bridge over the lip of the container floor, which typically sits several inches off the ground. It’s a simple addition that prevents injuries and makes moving goods in and out far more efficient.

Optimising Internal Organisation And Space

The final piece of the puzzle is making the internal space actually work for you. An empty container is just a big, echoing void. Without a plan, it quickly becomes a chaotic mess where things get lost, buried, or damaged.

Modular shelving systems are a complete game-changer here. They let you use the container's vertical space, allowing you to store far more stuff in a neat, accessible way. To get your setup just right, you can learn how to maximise space with smart storage in our detailed guide. You can also install partition walls to create separate zones for different uses, like an office area at one end and a storage section at the other.

Finally, you can't work safely or efficiently in the dark. While basic battery-powered lights are an option, a professionally installed electrical system with bright LED battens is the way to go. It provides consistent, reliable illumination, turning the container into a safe and productive environment, day or night.

Matching Accessories To Your Container's Job

Picking the right container accessories isn't about grabbing the most expensive or heavy-duty options off the shelf. It's about matching the gear to the specific job your container will be doing. A one-size-fits-all approach just doesn't cut it here. The perfect setup for a self-storage facility would be totally impractical on a construction site, and vice versa.

Think of it like choosing tyres for a vehicle. You wouldn't put slick racing tyres on a tractor destined for a muddy field, would you? In the same way, the accessories you pick should directly solve the daily challenges and operational demands of your container's environment. This way, you build a practical, cost-effective accessory package that actually adds value.

Of course, to properly kit out your container, you need to know its basic stats. For common sizes like the 40-footer, you can find a complete guide on 40 ft container dimensions. This foundational knowledge is crucial for planning internal layouts and any external add-ons.

The Self-Storage Facility Loadout

For anyone running a self-storage site, the priorities are dead simple: rock-solid security to give customers peace of mind, easy access for those same customers, and absolute control over moisture to protect their valuables. The entire facility's reputation hinges on keeping stored items safe and bone-dry.

A typical accessory package would look something like this:

- High-Security Lockboxes: These are non-negotiable. A tough, welded lockbox on every unit door is a massive deterrent and a physical barrier against break-ins.

- Personnel Doors: While you might not put one on every unit, installing easy-access personnel doors on some containers creates premium, user-friendly spaces that can command a higher rental fee.

- Grafotherm Anti-Condensation Coating: 'Container rain' is the enemy. A professional coating of Grafotherm stops condensation from forming and dripping, safeguarding everything from antique furniture to important documents.

The Construction Site Workhorse

On a busy UK construction site, a container pulls triple duty as a workshop, tool store, and break room. Here, the focus shifts to rugged durability, smart internal organisation, and pure on-site functionality. The environment is harsh, and the accessories have to be tough enough to take a beating day in and day out.

Consider this essential setup:

- Heavy-Duty Shelving Systems: Tools and materials need to be organised and within reach. Bolt-in, adjustable shelving brackets let you create sturdy, custom layouts that get equipment off the floor and easy to find.

- Electrical Fit-Outs: Power is a must-have for charging tools, running equipment, and lighting up the space. A professional electrical installation with bright LED lighting and plenty of sockets transforms a simple steel box into a productive workshop.

- Hardened Security: Construction sites are magnets for thieves. At a minimum, you need a combination of a heavy-duty lockbox and a high-grade padlock to protect expensive tools and machinery overnight.

The Remote Agricultural Solution

Out in the countryside, containers face a completely different set of challenges. They're often isolated, battered by the elements, and used for storing everything from expensive farm machinery to harvested crops. Security, ventilation, and self-sufficiency are the name of the game.

For agricultural use, a container must be a fortress against both thieves and the climate. Enhanced ventilation prevents produce from spoiling, while robust security protects vital equipment in isolated locations where no one is watching.

A practical loadout for a farm container includes:

- Enhanced Ventilation: Storing machinery that might still be damp or produce that releases moisture demands excellent airflow. A few static vents, or even a turbine vent, are vital for stopping rust and rot in their tracks.

- Robust Locking Mechanisms: When your container is in an isolated field, there's no substitute for serious security. A top-tier lockbox paired with an equally tough padlock is your first line of defence.

- Solar-Powered Lighting: Running mains power to a remote spot can be eye-wateringly expensive. Solar-powered LED lighting gives you a cost-effective, off-grid way to get into the container after dark.

Taking this targeted approach to selecting container accessories ensures your investment directly boosts the container's efficiency, security, and lifespan, no matter what you throw at it.

Protecting Contents From Moisture And Damage

While a high-security lockbox is a must for stopping thieves, the biggest threat to the goods inside your container is often something far more subtle. The internal environment itself—specifically moisture and temperature swings—can cause irreversible damage, from rust and mould to warped materials and ruined stock. Protecting your contents from these elements is a critical part of getting your container site-ready.

Two of the most effective lines of defence are specialised liners and robust condensation control. These container accessories don't just add a layer of protection; they actively manage the internal climate to keep your assets safe, dry, and in perfect condition, no matter what the British weather throws at them. This isn't just about preserving goods; it's about preserving their value.

Using Liners for Targeted Protection

Container liners are like a protective skin for the inside of your unit, creating a crucial barrier between your cargo and the container's steel walls. They're indispensable when you're transporting or storing sensitive materials, offering a focused solution for specific challenges.

There are two main types you'll come across:

- Thermal Liners: Think of these as a giant insulated foil bag for your container. They're designed to reflect radiant heat and shield temperature-sensitive goods—like food, pharmaceuticals, or electronics—from extreme heat or cold.

- Bulk Liners: These are heavy-duty, woven liners used to transport loose, dry materials such as grain, sand, or chemical powders. They effectively turn a standard container into a sealed, clean, and contamination-free bulk transport unit, preventing product loss and making clean-up much easier.

The market for these protective accessories is growing, driven by increasing trade volumes and environmental policy. For instance, polypropylene (PP) liners are on track to make up roughly 30.6% of the global liner market by 2025, largely because they are lightweight yet incredibly strong.

Winning the War Against Condensation

The most common—and destructive—environmental problem inside a container is 'container rain'. This happens when temperature changes cause moisture in the air to condense on the cold ceiling and walls, dripping down onto everything below. It's a silent destroyer that can wreak havoc if you don't get it under control.

A container suffering from condensation is like a terrarium gone wrong. The sealed environment traps moisture, creating a perfect breeding ground for mould, mildew, and corrosion. Effective moisture control isn't just a recommendation; it's essential for long-term storage.

Luckily, there are several proven ways to fight back, each with different costs and levels of effectiveness.

Head-to-Head Condensation Solutions

Choosing the right approach comes down to your specific needs, your budget, and the value of the goods you're protecting.

- Desiccant Bags: These are the simplest solution. Large, absorbent bags filled with silica gel or calcium chloride are hung from the container's lashing rings to soak up airborne moisture. They're cheap and cheerful for short-term use but need to be replaced regularly.

- Passive Vents: As we've mentioned before, installing vents creates airflow, letting damp, warm air escape before it can condense. This is a permanent, low-maintenance solution that makes a huge difference to the internal climate. A proper door seal is also crucial to stop excess moisture getting in in the first place; our guide on seals for containers offers more advice on this.

- Anti-Condensation Coatings: For the ultimate protection, a specialised spray-on coating like Grafotherm can be applied to the interior ceiling. Its textured surface absorbs forming moisture like a sponge and releases it back into the air as vapour when conditions improve, stopping drips completely.

When thinking about protecting sensitive electrical gear inside your container, it's also worth understanding the various types of electrical boxes and weatherproof enclosures available to ensure they're shielded from any potential moisture. By combining these strategies, you can create a stable, dry environment.

Putting It All Together: Installation, Maintenance, and Safety

Picking out the right container accessories is half the battle. The other half? Getting them installed correctly, keeping them in good nick, and making sure everything is safe and sound. A badly fitted lockbox or a dodgy light fitting isn’t just a nuisance—it’s a safety risk and a waste of a good investment.

Think of this section as your hands-on manual for getting the most from your container upgrades. We’ll walk through some solid installation tips, a simple maintenance schedule to keep everything running smoothly, and the essential safety rules you need to follow here in the UK.

Best Practices for Accessory Installation

How you attach an accessory is just as important as the accessory itself. When it comes to fitting things like lockboxes or vents, you’re generally looking at two methods: welding or bolting. Each has its place.

Welding vs. Bolting: A Quick Comparison

| Method | The Good | The Not-So-Good | Best For |

|---|---|---|---|

| Welding | Creates the strongest, most permanent, and most secure bond possible. When done right, it’s completely weatherproof. | You’ll need a skilled professional welder and their gear. It permanently alters the container and voids the CSC plate. | High-security gear like lockboxes where you absolutely cannot compromise on strength. |

| Bolting | Often a straightforward DIY job with basic tools. It also means you can move or remove accessories later on. | Can create spots for water to get in if you don't seal it properly. It can also be less secure, as bolts can be messed with. | Vents, shelving brackets, and other non-structural bits where you might want some flexibility down the line. |

When you’re deciding where to put things, think about how they work. Vents, for example, are most effective when they create a natural airflow. Stick one low down on one wall and another up high on the opposite side. This lets cool, dry air come in and push the warm, moist air out. Simple but effective.

Your Simple Container Maintenance Checklist

A few minutes of prevention can save you a lot of headaches and money. A quick look-over every few months will keep your container and its accessories in top condition and extend their lifespan.

Here's what to keep an eye on:

- Inspect All Seals: Check the rubber gaskets around the main cargo doors, plus any personnel doors or windows you’ve fitted. Look for cracks, splits, or any signs of perishing rubber that could let water in.

- Clear Vents and Drains: Make sure your vents are clear of leaves, dirt, or anything else that could block airflow. Don't forget to check that the corner casting drains are clear to stop water from pooling on the roof.

- Test Security Hardware: Open and close the locks on all your doors and lockboxes. Do they work smoothly? A quick spray of lubricant can stop them seizing up, especially in our damp UK weather.

- Check Electricals: If you have lights or power points, give them a quick visual check. If you spot any flickering or obvious faults, kill the power and call a qualified electrician straight away. Don't take chances.

Understanding Safety and UK Compliance

Safety isn't just a box to tick; it's a legal must-have. When you start modifying a shipping container, you introduce new risks that need to be managed properly.

Any time you cut into a container's corrugated steel walls, you're changing its structural integrity. It's vital to know that this will invalidate the container's CSC (Convention for Safe Containers) plate. This makes it unsuitable for international shipping unless it's re-certified by an official body.

For static storage on-site, a CSC plate isn't needed, but you still need the container to be structurally sound. When it comes to electrics, there are no exceptions: all work must be done by a qualified electrician who can certify it to UK standards (BS 7671). This is non-negotiable for your safety and for your insurance.

Finally, if you’re lifting or moving a modified container, always use certified lifting gear. Make sure the total weight of the container—including everything inside and all your accessories—is within the safe working load of your equipment.

Finding and Vetting a Reliable UK Supplier

Picking the right container accessories is only half the battle. Your choice of supplier is just as crucial, and a good UK-based partner offers more than just products—they bring expertise, ongoing support, and quality assurance to the table. Taking the time to find a trustworthy supplier means you’ll get durable components and dependable service long after the first invoice is paid.

The first step? Sizing up a supplier’s credibility. Don’t just be impressed by a slick website. You need to look for real-world signs of a reputable business, like clear contact details, a physical UK address, and detailed product specs. Genuine customer testimonials and straightforward pricing are also great signs of a company that stands by what it sells.

Key Questions To Ask a Potential Supplier

Before you commit, it’s vital to ask a few pointed questions. A good supplier will welcome your enquiries and give you clear, confident answers. This first conversation tells you a lot about their business practices and the quality of their gear.

Here are a few essentials to throw at them:

- What are the material specifications? Ask about the grade of steel used in their lockboxes or the type of rubber in their seals. Vague answers are a massive red flag.

- What warranty do you offer? A proper warranty shows they have confidence in how long their products will last.

- Do you provide technical support after the sale? Knowing you can ring someone up for advice on installation or maintenance is invaluable.

- What are the logistical arrangements? Get the details on delivery times, costs, and whether items turn up flat-packed or pre-assembled.

A supplier’s true value is revealed in their support and transparency. If they can’t provide detailed data sheets or a clear warranty policy, it’s often a sign that the product quality may be just as ambiguous.

For many businesses, especially construction firms and facility managers, getting a good deal is also a priority. Don’t be shy about asking for trade discounts on bulk orders or for repeat business. Many specialist suppliers offer better pricing for commercial clients, which can seriously reduce the overall cost of a big project.

Finally, think about the bigger picture. Are you just buying individual accessory kits to fit yourself, or do you need a supplier who can deliver pre-modified containers? Understanding the cost and logistical differences between these options is key. For more guidance on the procurement process, our detailed article on buying storage containers offers some extra valuable insights. Vetting your supplier thoroughly from the start is the best way to ensure a smooth ride.

Got Questions? We’ve Got Answers

Thinking about adding a few extras to your container? It’s only natural to have a few questions, especially when you’re dealing with the practicalities and the rules here in the UK. Getting these things straight before you start is the best way to make sure your project goes off without a hitch.

Here are the straightforward answers to the questions we hear most often.

Do I Need Planning Permission To Add Accessories To My Container In The UK?

This is the big one, and the short answer is: it depends. It usually comes down to three things: what you’re using the container for, where it’s located, and how long it’s going to be there. For something temporary, like using it for on-site storage during a build, you’re probably in the clear.

But the game changes if you’re turning it into something more permanent. If you’re cutting in windows and personnel doors to create a workshop or a site office, you’ll almost certainly need to have a chat with your local planning authority. Every council has slightly different rules, so our advice is always check with them directly before you start making any serious modifications.

Can I Install Container Accessories Myself Or Should I Hire A Professional?

This really boils down to the accessory in question and how handy you are with a toolkit. Plenty of the simpler, bolt-on bits and pieces are well within the reach of a competent DIYer.

-

Good for DIY: Things like installing shelving brackets, fitting a bolt-on lockbox, or adding simple vents can usually be tackled with standard tools and a bit of confidence. Just make sure you follow the manufacturer's instructions to the letter.

-

Leave it to the Pros: Any job that means cutting into the container’s steel walls—for windows, doors, or larger vents—needs a professional touch. You need proper fabrication and welding to maintain the container's structural integrity and get a truly weatherproof finish. And this is non-negotiable: all electrical work, like wiring in lights or power sockets, must be done by a qualified electrician to meet UK safety regulations (BS 7671).

Will Adding Accessories Invalidate My Container's CSC Plate?

Yes, it’s almost a certainty. Any structural change, no matter how small, will invalidate a container's CSC (Convention for Safe Containers) plate. That includes welding on a lockbox, cutting an opening for a vent, or putting in a new door.

An invalidated CSC plate means the container is no longer certified for its original purpose: international shipping by sea or rail. If you plan to ship the container after you’ve modified it, you'll need to get it inspected and re-certified by an authorised body. However, if it's just for static, on-site storage, a valid CSC plate isn't necessary.

For everything from high-security lockboxes to clever ventilation solutions, Quickfit Container Accessories has you covered with quality parts and expert advice.