A UK Guide to Shipping Container Doors

When it comes to shipping containers, the doors are everything. They’re the first line of defence for security, your main point of access, and what keeps the unpredictable UK weather out. Picture a standard container as a steel vault; its original cargo doors are the heavy-duty vault door, built to withstand the toughest conditions at sea.

More Than Just an Entry Point

It's easy to overlook shipping container doors, but they completely define how you can actually use the container. Those original, heavy-duty cargo doors are brilliant for keeping goods safe during a rough voyage, but for daily use back on land—whether it’s a storage unit, a workshop, or a site office—they can be a real pain. Their sheer weight and complex locking gear are designed for maximum security, not day-to-day convenience.

This is where customisation really comes into its own. Choosing the right door can transform a simple steel box into a functional, accessible space that’s built for your exact needs. It’s the difference between wrestling with a cumbersome vault and walking into a user-friendly room.

Beyond the Standard Cargo Door

Let’s look beyond the factory-fitted doors. The right modification can completely change how a container works for you, making it far better suited for its new life.

- Personnel Doors: Just like a door on a house or office, these offer simple, key-lockable access. They’re perfect for converting containers into workshops, site offices, or any secure storage unit you need to get into frequently.

- Roller Shutter Doors: A fantastic choice when you’re tight on space. Roller shutters open vertically, so you don’t need any swing room. This makes them a go-to for self-storage sites and workshops where you're moving vehicles or bulky equipment in and out.

- Glazed or Sliding Doors: If you're converting a container into a garden room, a pop-up café, or a retail unit, these doors are a game-changer. They let in natural light and create a much more welcoming and open feel.

The Foundation of UK Trade and Storage

The need for secure and functional container doors is a big deal, especially when you consider their role in the UK economy. The UK shipping industry is a huge part of our national commerce, directly employing over 98,000 people and supporting more than 728,000 jobs in the wider economy.

Think about this: in 2023 alone, UK ports handled a staggering 434.9 million tonnes of cargo. The integrity of every single one of those containers is non-negotiable, and it all comes down to the doors protecting the valuable goods inside. To get a better sense of the scale, you can learn more about the UK shipping industry's economic impact on safety4sea.com.

At the end of the day, getting to grips with the different types of shipping container doors is the key. It lets you move beyond the container’s original design and unlock its true potential.

Finding the Right Door for Your Container

Choosing the right door for a shipping container isn't like picking from a catalogue. It's about matching the entry point to its real-world purpose. The original, factory-fitted cargo doors are absolute marvels of engineering—built from heavy-gauge steel, they offer security that's second to none. But for a container repurposed here in the UK for daily access, their sheer bulk often becomes more of a hindrance than a help.

Imagine having to unlock a bank vault every time you need to grab a spanner. That’s what using original cargo doors can feel like for a site office or workshop. They were designed for one thing: keeping cargo secure and weatherproof during rough sea transit, not for popping in and out quickly. This is precisely why looking into alternative shipping container doors is a must for almost any modification project.

Matching the Door to Your Daily Needs

First things first, you need to be honest about how you'll use the container. Is it a long-term storage space you'll dip into once a month, or a busy workshop with people coming and going all day? The answer to that question will point you straight to the most suitable door type. Infrequent access might make the original doors bearable, but high-traffic use screams for a more practical solution.

Let's walk through the most common alternatives and where they shine. Each option is a trade-off between convenience, security, and cost, so getting your head around these differences is key.

-

Steel Personnel Doors: These are the go-to for convenient, everyday access. Just like a standard door on a house or commercial building, they come with key locks and handles, making entry quick and simple. They're perfect for container offices, workshops, or secure storage units where you need to get in and out without a fuss.

-

Roller Shutter Doors: A brilliant solution when space is tight. Because they open vertically, they don't need any swing clearance, making them ideal for cramped spots. This makes them a popular choice for self-storage facilities and garages where you might be driving a vehicle or forklift right up to the entrance.

-

Glazed Sliding Doors: When a container is being transformed into a liveable space—think a garden room, a pop-up café, or a retail outlet—these doors are a superb choice. They let natural light flood the interior, creating a much more open and inviting atmosphere that solid steel doors simply can't match.

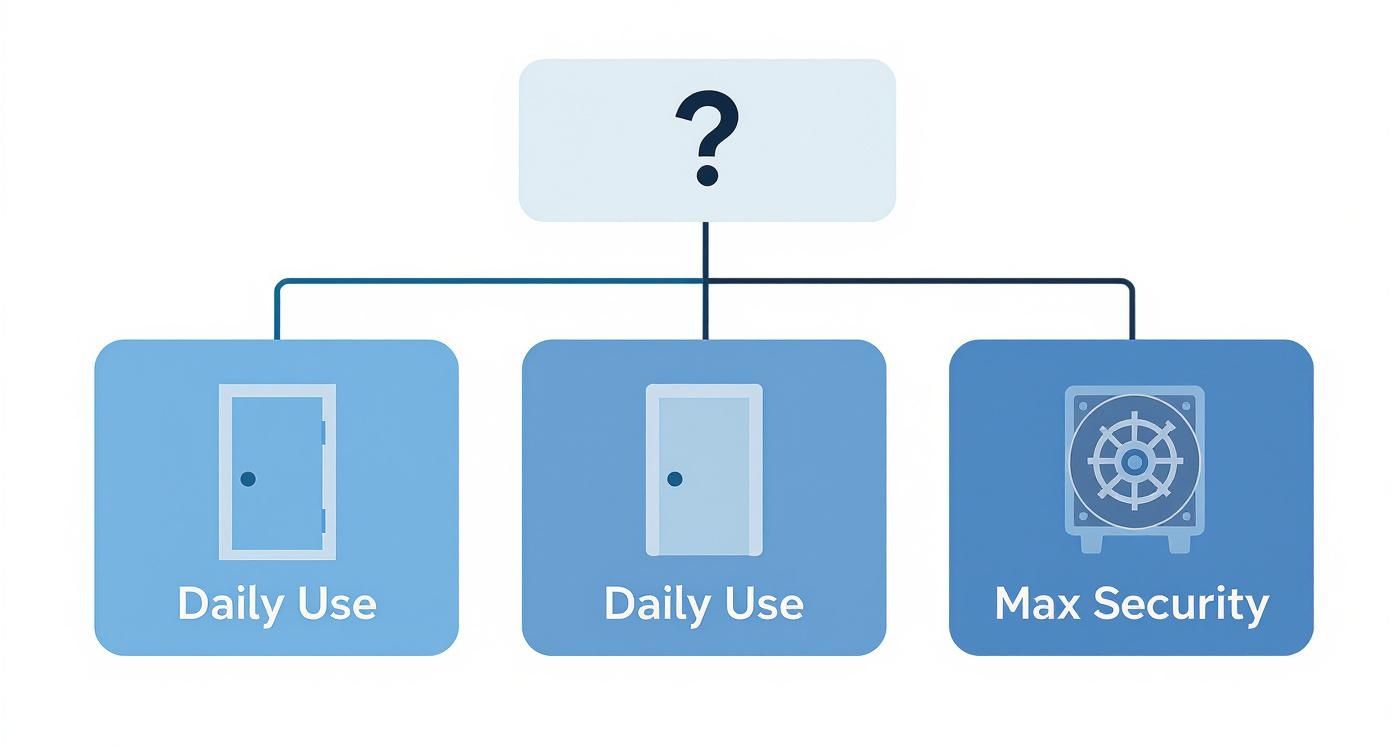

To make this choice a bit easier, the diagram below shows how your core needs influence the decision.

As you can see, it often comes down to a balance: the maximum security of the original cargo doors versus the sheer ease of use offered by retrofitted alternatives.

A Practical Comparison of Container Door Options

To help you weigh the pros and cons, this table compares the features, best uses, and typical costs of different container door options, helping you make an informed choice for your project.

| Door Type | Best For | Material | Pros | Cons |

|---|---|---|---|---|

| Original Cargo Doors | Maximum security, long-term storage, shipping | Heavy-gauge COR-TEN steel | Unbeatable security, weatherproof, durable | Cumbersome, slow to open, requires lots of space |

| Steel Personnel Door | Daily access, offices, workshops, secure storage | Galvanised steel | Convenient, easy to use, good security | Less secure than cargo doors, requires cutting the container |

| Roller Shutter Door | Tight spaces, garages, frequent vehicle access | Steel or aluminium | Space-saving vertical opening, wide access | Can be noisy, requires more maintenance, security varies |

| Glazed Sliding Door | Habitable spaces, retail, cafes, garden rooms | Glass with aluminium/uPVC frame | Lets in natural light, aesthetically pleasing | Least secure option, less insulated than steel doors |

Each door has its place, and understanding these differences is the key to getting your container conversion right from the start.

Analysing the Trade-Offs

No single door is perfect for every job; each comes with its own set of compromises. Getting to grips with these is crucial for making a decision you won't regret down the line.

A container's functionality is ultimately defined by its accessibility. The most secure container in the world is useless if you can't get into it efficiently when you need to. The right door bridges the gap between raw security and practical, everyday usability.

Original cargo doors provide the highest level of security but are slow to operate and require a fair bit of muscle. A steel personnel door offers brilliant convenience, but its security level—while high—depends entirely on the quality of the lock and the installation of the frame. Roller shutter doors are incredibly space-efficient, but their maintenance can be more involved than a simple hinged door. And finally, glazed doors offer fantastic visual appeal and light but are naturally less secure than solid steel, making them better for supervised or low-risk environments.

Ultimately, picking the right door means carefully weighing up your project's specific needs in the UK, from the rugged demands of a building site to the welcoming entrance of a pop-up shop.

Securing Your Container Against Threats

Let’s be honest, a shipping container is only ever as secure as its weakest point. And nine times out of ten, that’s the door. Bolstering your container doors isn't just a final touch; it’s one of the most important steps you can take to protect whatever you’ve got stored inside. The best way to think about it is in layers, just like a home security system. This approach turns a simple steel box into a proper safe.

The standard cargo doors on a shipping container are already pretty tough. They’re built with heavy-gauge steel and beefy locking bars designed to survive rough seas and international transit, so you’ve got a solid starting point. However, when a container is just sitting on a site here in the UK, those built-in features need a few upgrades to stop determined thieves in their tracks.

Building Your Layers of Defence

Your first line of defence is a high-quality padlock. It’s the most basic element, but it’s absolutely essential. The problem is, even the strongest padlock can be a target for tools like angle grinders or bolt cutters if it's left exposed.

That’s where the second, much tougher layer comes in: a steel lockbox. A lockbox is essentially a thick steel cowl that’s welded directly onto the container doors. It completely covers the padlock, leaving only the keyhole accessible from underneath. This simple addition makes it nearly impossible for bolt cutters to get a grip on the padlock shackle, instantly levelling up your container's security.

Secure storage is a booming business across the country. The UK shipping container market is growing steadily, with a projected compound annual growth rate (CAGR) of around 3.08% from 2023 to 2033. A huge driver for this is the explosion in UK e-commerce, which is expected to hit an incredible 93% penetration rate by 2028. This surge means more goods need storing, and that means more containers need reliable, secure doors.

Advanced Security Enhancements

If you’re storing high-value items, it’s worth looking beyond the lockbox. These advanced measures are all about reinforcing other potential weak spots and adding a few internal tricks.

- Internal Locking Mechanisms: These systems are fitted on the inside of the door and operated by a key from the outside. Because the mechanism is hidden from view and protected by the steel door itself, it’s a real headache for anyone trying to tamper with it.

- Hinge Reinforcement: It’s less common, but a determined thief might try to attack the door hinges. Welding the hinge pins or adding reinforced protectors can stop them from being cut or forced, making sure the doors can’t just be lifted off their frame.

- Frame Reinforcement: The door frame is just as important as the door. A frame that’s straight and undamaged, with intact seals, doesn't just keep the weather out—it ensures a tight fit that’s much harder for someone to pry open.

"A proactive security strategy focuses not just on the lock, but on the entire door assembly. By reinforcing hinges, shrouding the padlock, and considering internal mechanisms, you create a system where every potential point of failure is addressed."

By putting these strategies into practice, you can massively increase the security of your shipping container doors. For some excellent insights on protecting your assets, especially after a container has been compromised, check out this guide on securing a storage container.

Ultimately, the best protection comes from a multi-layered approach. Start with a robust padlock, add a lockbox, and then consider extra reinforcements. This creates a formidable barrier against anyone who shouldn’t be there. For a more detailed look at the options available, you can read our comprehensive guide on shipping container security measures. This strategy ensures your container isn't just a storage unit, but a secure vault for your valuables.

Getting Doors Installed and Customised

Adding a new door is what really turns a shipping container from just a big steel box into a genuinely useful space. Cutting into a container might sound like a huge job, but once you understand the basics, it's not as intimidating as it seems. Let's break down what's involved in installing and customising shipping container doors, whether you're thinking of tackling it yourself or hiring a pro.

At its heart, the job is about retrofitting a new door—like a steel personnel door or a roller shutter—into one of the container's corrugated walls. This isn’t a simple cut-and-paste task; it demands precision and a good feel for the container's structure. Get it right, and you transform a cumbersome storage unit into an accessible workshop, office, or secure lock-up.

The Step-by-Step Retrofitting Process

Installing a new door is a methodical job. While the exact details might change depending on the type of door you're fitting, the core steps are pretty much the same. It's a real mix of heavy-duty work and fine-detail finishing to get a result that's both secure and completely weatherproof.

A typical installation looks something like this:

- Measure and Mark Out: Accuracy is everything here. The first job is to meticulously measure and mark the opening on the container wall. You have to account for the door and its frame to ensure you get that perfect, snug fit.

- Cut the Aperture: This is where the sparks fly. Using an angle grinder or a plasma cutter, the marked-out section of the corrugated wall is carefully removed. It’s the most critical part of the process—a clean, straight cut is non-negotiable for a professional finish.

- Weld in the Frame: The new door frame, usually a steel box section, is then slotted into the opening. It has to be perfectly level and square before it’s welded securely into place. This creates a solid new structure for the door to hang from.

- Install the Door: With the frame set, the new door is hung. All the hardware, from hinges to locks, gets fitted and adjusted to make sure it swings smoothly and closes flush against the frame.

- Seal and Weatherproof: The final, crucial touch. A weatherproof sealant, like silicone or a rubber gasket, is applied all the way around the frame. This is what stops water and draughts from getting in, keeping your container protected from the notoriously damp UK climate.

Tackling Common Installation Hurdles

Fitting a door into a shipping container throws up a couple of unique challenges. The biggest one is dealing with the corrugated steel walls. It's not a flat surface, so the frame has to be set just right to get a perfect seal. Often, infill panels are welded into the gaps between the frame and the corrugations to create a smooth, continuous surface for the sealant to adhere to.

Another major point is maintaining the container's structural integrity. You're cutting a big hole in the wall, which can weaken the structure if you're not careful. For larger openings, like those needed for roller shutter doors, it's often essential to weld in extra steel reinforcements around the aperture. This helps redistribute the load and keeps the container as strong as it was designed to be.

The real secret to a great door installation is in the details. A perfectly cut opening and a meticulously welded frame are what separate a professional, leak-proof job from a problem waiting to happen. It’s all about respecting the container's structure while adapting it for a new life.

Beyond Installation: Customisation Options

Once your new door is in, the customisation possibilities are endless. These extra touches can boost the door's functionality, making the container even better suited for whatever you have planned. Popular upgrades usually focus on improving security or adding practical accessories.

Consider adding some of these functional upgrades:

- Vision Panels: A small, reinforced glass window in a personnel door lets natural light flood in without creating a security weak spot. It’s a brilliant addition for workshops or site offices.

- Louvred Vents: Installing vents, either in the door itself or alongside it, is great for improving airflow. This is vital for stopping condensation and keeping the air quality fresh inside.

- Specialised Hardware: You can tailor the door's function to meet specific safety or security needs by upgrading to high-security locks, adding panic bars for emergency exits, or fitting door closers.

Whether you need to replace a damaged locking bar or want to add a new vent, getting the right parts is essential. You can find a huge range of specialised container door parts to help you finish any customisation or repair job, allowing you to tweak your container doors to meet your exact requirements.

Keeping Your Container Doors in Top Condition

Regular maintenance is the secret to a long life for any shipping container door, especially when it's battling the famously damp UK climate. Think of it like servicing your car; a bit of preventative care goes a long way in dodging expensive repairs down the road. A simple maintenance plan will keep your doors swinging freely and ensure your container stays secure and weatherproof for years.

The process kicks off with simple visual checks. The usual suspects you’ll find are small rust spots, tired-looking rubber door seals, and stiff locking bars or hinges. Nipping these problems in the bud is crucial. A small patch of surface rust can spread like a rash, and a torn gasket is an open invitation for water damage inside your container.

A Simple Maintenance Routine

A proactive approach to upkeep will save you a world of time and money. By setting aside a small amount of time every few months for these tasks, you can dramatically extend the life of your shipping container doors and stop small issues from snowballing into major headaches.

Your routine should zero in on three key areas:

- Rust Treatment: Pay close attention to corners, welds, and the bottom edges where water loves to sit. If you spot any surface rust, it needs dealing with promptly before it starts eating through the steel.

- Lubrication: Hinges and locking mechanisms are the workhorses of your container doors. Keeping them well-lubricated is the key to smooth, easy operation and helps push out moisture that can cause them to seize up.

- Seal Inspection: The rubber gaskets framing the doors are your main defence against the elements. They need to be checked regularly for any signs of cracking, splitting, or perishing.

"Effective container maintenance is fundamentally about prevention. A ten-minute inspection every season can identify a rust patch or a worn seal, preventing a repair bill that could easily run into hundreds of pounds."

Step-by-Step Care and Troubleshooting

Let’s break down the practical steps to keep everything in working order. Tackling surface rust is straightforward: just sand the area back to bare metal, apply a coat of rust-inhibiting metal primer, and finish with a durable, marine-grade paint that matches the container. This simple action stops corrosion dead in its tracks.

For hinges and locking bars that have become stiff, a high-quality grease or heavy-duty lubricating spray is your best friend. Work it thoroughly into all the moving parts, opening and closing the door a few times to make sure it spreads evenly. This not only makes the doors easier to use but also protects the mechanisms from wear and tear.

If a door gasket is damaged, it needs replacing—no two ways about it. A compromised seal is a welcome mat for water, pests, and draughts. You can find replacement gaskets designed for a perfect fit, restoring your container’s all-important weatherproof seal.

While container doors have their own quirks, many principles of keeping them in top shape are universal. For a broader perspective, this general door maintenance guide covers a lot of similar ground.

To help you stay on track, a simple seasonal checklist can be a lifesaver. It’s an easy way to make sure nothing gets missed.

Seasonal Maintenance Checklist for Container Doors

| Task | Frequency | Tools/Materials Needed | Key Focus |

|---|---|---|---|

| Visual Inspection | Quarterly | None | Check for rust, dents, and warping. |

| Seal Check | Quarterly | Clean cloth | Inspect gaskets for cracks, tears, or brittleness. |

| Hinge Lubrication | Bi-Annually | Heavy-duty grease/lubricant | Apply to all hinge pins and moving parts. |

| Locking Bar Care | Bi-Annually | Grease, wire brush | Clean and lubricate locking bars and cams. |

| Rust Treatment | As needed | Sandpaper, primer, paint | Address any surface rust spots immediately. |

| Drainage Check | Quarterly | Small brush or wire | Ensure drain holes at the bottom are clear. |

This checklist is a great starting point for building a routine. A few minutes each season is all it takes to keep things running smoothly.

By following these simple, actionable tips, any container owner can keep their doors functioning securely and reliably. For a more detailed walkthrough, our complete checklist for container door maintenance provides a comprehensive resource to guide you through every step.

Frequently Asked Questions

We get asked a lot of the same questions about container doors, so we've put together some clear, straight-to-the-point answers to help you out.

Can I Fit a Normal House Door to a Shipping Container?

Technically, you could, but it’s a terrible idea. A standard house door and its wooden frame are simply not built for the job. They can't properly integrate with the container's corrugated steel walls and won't last long against the UK's damp climate.

You'd be sacrificing durability, security, and weatherproofing. The right tool for the job is a purpose-built steel personnel door, which is designed to create a proper seal and offers far more resistance to anyone trying to break in.

Why Are Original Shipping Container Doors So Hard to Open?

There are a couple of reasons why original cargo doors can feel like a workout to open. If the container isn't sitting on perfectly level ground, the whole frame can twist just enough to make the doors bind and stick.

Also, these doors are designed to create an immense amount of compression on their rubber seals. This is what keeps them completely watertight during violent storms at sea, but it also creates a lot of resistance. Giving the hinges and locking bars a regular dose of lubricant can make a world of difference.

Remember, those original doors were engineered for maximum security and weatherproofing on a cargo ship, not for the convenience of daily use. Their sheer toughness is why they can be so difficult to operate.

Do I Need Planning Permission in the UK to Add a New Door?

In most cases, if you're just using the container for simple storage on your own property, adding a new door does not require planning permission.

However, that changes if you're converting the container into something habitable or commercial—like an office, a workshop, or a pop-up shop. You'll also likely need permission if the container is in a conservation area or an Area of Outstanding Natural Beauty. It’s always best to have a quick chat with your local council before you start any work, just to be sure.

What Is the Best Way to Prevent Rust on My Container Doors?

The single most effective thing you can do is keep an eye on them. Regularly check for any scratches, chips, or dings in the paintwork. Pay close attention to the areas around the hinges, locking bars, and the bottom edges, as that's where water loves to sit.

If you spot any surface rust, you need to deal with it straight away. The fix is pretty straightforward:

- Sand the rusty patch right back to the bare metal.

- Apply a good-quality, rust-inhibiting metal primer.

- Finish it off with a couple of coats of durable, marine-grade paint to seal it up.

Keeping the moving parts and hinges well-greased also helps push moisture away and stops corrosion from getting a foothold.

Whether you need high-security lockboxes, replacement door gaskets, or vents, Quickfit Container Accessories has you covered for all your container maintenance and customisation jobs. Check out our huge range of parts and get next-day UK delivery. Visit us at https://www.quickfitcontaineraccessories.co.uk to find what you need.