How Many Pallets in a 40ft Container? A Complete UK Guide

When you're planning a shipment, the first question on your mind is probably a simple one: just how many pallets can you actually cram into a 40ft container?

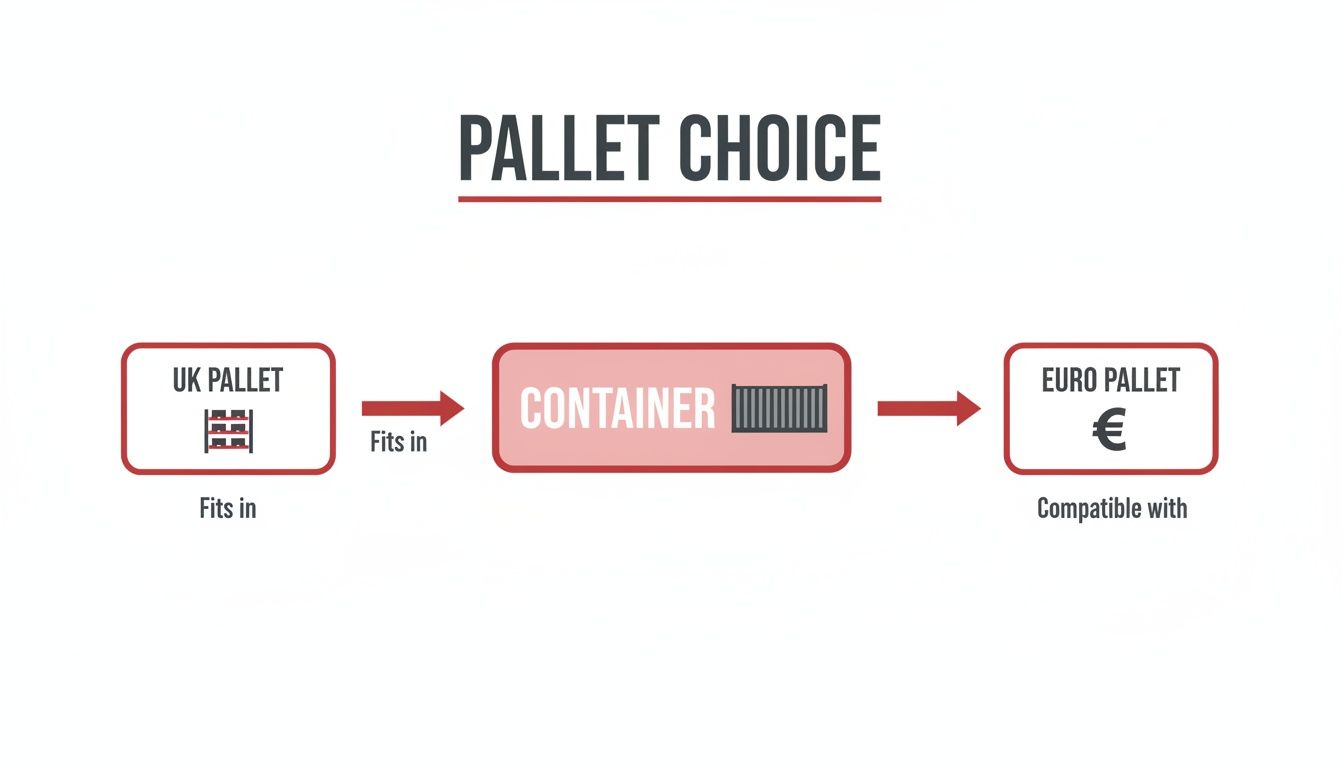

It's the million-pound question in logistics. The quick answer is that a standard 40ft container will hold around 20 to 21 Standard UK pallets (1200x1000mm) or 24 to 25 Euro pallets (1200x800mm), arranged in a single layer. The final number always comes down to the pallet type you're using and how you load them.

Your Quick Answer for 40ft Container Pallet Capacity

Figuring out the exact pallet count for a 40ft shipping container is a cornerstone of good logistics planning. While those ballpark figures are a great starting point, your real-world capacity is shaped by a few key things: the specific pallet size, the container's internal dimensions, and your loading strategy.

For example, that seemingly small difference between a Standard UK pallet and a Euro pallet makes a huge impact. The slightly narrower profile of a Euro pallet often allows for a much more efficient layout, letting you squeeze in a few more. Across the full length of a container, those little optimisations really add up.

Standard Benchmarks in UK Logistics

Across the UK logistics industry, the go-to figure for a standard 40ft container is 21 UK pallets, each measuring 1200mm x 1000mm. A typical 40ft box has internal dimensions of roughly 12.06m (L) × 2.34m (W) × 2.38m (H), which is perfectly suited to fit either 21 Standard UK pallets or 25 Euro pallets on the floor.

This isn't an accident. UK pallet manufacturers and pallet pool providers design their systems around this geometry because it makes planning full-container loads for both domestic and international freight so much smoother. If you want to dive deeper into how freight forwarders tackle this, you can get some great insights on container loading strategies from Barrington Freight.

To make your life easier during the initial planning stages, we've put together a quick-reference table. It breaks down the typical pallet capacity for both standard 40ft containers and their taller cousins, the 40ft High Cube.

A High Cube (HC) container gives you an extra foot of vertical space compared to a standard General Purpose (GP) container. While this doesn't change the floor footprint or how many pallets you can fit in one layer, that extra height is invaluable for tall cargo or if you plan on double-stacking—provided your goods are stable and you don't exceed the weight limit.

40ft Container Pallet Capacity at a Glance

This quick reference table gives you the essential numbers you need for initial planning, whether you're working with standard or high cube containers.

| Container Type | Standard UK Pallets (1200x1000mm) | Euro Pallets (1200x800mm) |

|---|---|---|

| 40ft Standard (GP) | 20–21 Pallets | 24–25 Pallets |

| 40ft High Cube (HC) | 20–21 Pallets (on the floor) | 24–25 Pallets (on the floor) |

Think of this table as your starting block. It gives you the raw numbers for a quick estimate. In the sections that follow, we'll get into the nitty-gritty behind these figures, exploring everything from precise container dimensions and pallet layouts to real-world constraints like payload weight that will ultimately dictate your final load.

Understanding The Space Inside Your 40ft Container

Before you can even begin to think about how many pallets you can squeeze into a 40ft container, you need to get familiar with the space you're actually working with. It's easy to get fixated on the external length, but when it comes to loading cargo, it’s the internal, usable dimensions that really matter. These numbers are the foundation for every decision you'll make, from which pallets to use to how you arrange them.

Think of it like furnishing a room. You wouldn't buy a massive sofa based on your house's outside measurements; you'd measure the living room's internal walls. A 40ft container is no different—its true capacity is what’s inside the steel frame.

For pallet loading, these are the dimensions you need to commit to memory:

- Internal Length: Approximately 12.03 metres (39 feet 5 inches)

- Internal Width: Approximately 2.35 metres (7 feet 8 inches)

- Internal Height: Approximately 2.39 metres (7 feet 10 inches)

While these figures can vary slightly from one manufacturer to the next, they give you a solid baseline for planning your shipment. For most single-layer loads, it's the internal width that becomes the biggest headache, as it directly dictates how many pallets you can fit side-by-side.

Standard (GP) vs High Cube (HC) Containers

When you book a 40ft container, you'll usually be offered two main options: the Standard, often called a General Purpose (GP), and the High Cube (HC).

The difference is brilliantly simple: a High Cube container is taller. Both have the exact same floor footprint, but the HC gives you an extra foot of precious vertical space. It's like comparing a room with a standard ceiling to one with a vaulted ceiling—the floor plan is identical, but the vaulted room feels way more spacious and can handle taller furniture.

A High Cube container provides an internal height of approximately 2.70 metres (8 feet 10 inches). This additional height makes no difference to the number of pallets on the floor but is invaluable for tall goods or double-stacking lighter cargo.

For businesses shipping bulky but lightweight items, that extra foot is a complete game-changer, often leading to huge gains in volume. While we're focused on 40ft containers here, you can explore the dimensions of a 20-foot shipping container to see how these same principles apply to the smaller units.

The Importance of Usable Floor Space

At the end of the day, every pallet loading puzzle starts and ends with the container's floor. The internal length and width create your total usable floor area, which is essentially the canvas for arranging your pallets. A smart loading plan is all about covering as much of this floor as possible, leaving no awkward or wasted gaps.

This is where the geometry of your pallets really comes into play. A tiny change in pallet dimensions can completely alter how efficiently you use that finite space. For businesses obsessed with maximising every cubic metre, it's even worth exploring alternatives like pallet-less shipping with slip sheeting, which gets rid of the bulky pallet altogether.

Getting a solid grasp of these fundamental measurements—length, width, and height—is the first real step to mastering container logistics. Once you know your numbers, you can stop guessing and start making informed decisions that optimise every single shipment and get the most bang for your transport buck.

Choosing Between UK and European Pallet Sizes

Choosing a pallet might seem like a minor detail, but it’s one of those decisions that can make or break your container load plan. The wrong choice means wasted space and higher costs. Here in the UK, the logistics world really runs on two main workhorses: the Standard UK Pallet and the Euro Pallet.

Getting to grips with the subtle but critical differences between them is the key to packing your 40ft container like a pro. These two pallet types didn’t just appear out of thin air; they were engineered to solve very different logistical puzzles, and their dimensions are a direct result of the transport systems they were built for.

The Standard UK Pallet

Measuring 1200mm x 1000mm, the Standard UK Pallet is the backbone of domestic logistics. Its larger size was designed to fit perfectly inside the dimensions of standard UK lorries and slot neatly into British warehouse racking. For moving goods from a factory to a distribution centre within Great Britain, it was the most efficient tool for the job.

But here’s the catch: its design came about long before ISO shipping containers became the global standard. Because of this, its dimensions just don’t mesh cleanly with the internal width of a 40ft container. That slight mismatch is exactly why you can never quite get a perfect fit, which is why a 40ft container usually maxes out at around 20-21 UK pallets.

The Euro Pallet

The Euro Pallet, on the other hand, comes in at a slightly smaller 1200mm x 800mm. This pallet was built from the ground up with cross-border European transport in mind. Its narrower profile was optimised to slide efficiently into European railway carriages and, most importantly for us, ISO shipping containers.

That intentional design choice gives it a huge advantage when you’re planning an international shipment. The 800mm width allows for a much tighter, more flexible arrangement inside the container’s 2.35m internal width. It’s this superior spatial efficiency that lets you consistently load more of them—typically 24-25—into the exact same 40ft space.

Key Takeaway: The difference isn't just about size; it's about history. The UK pallet was built for British lorries and warehouses. The Euro pallet was engineered for seamless international freight, making it a natural fit for shipping containers.

This choice has a direct impact on your bottom line. While the UK's traditional 1200mm x 1000mm pallet is optimised for our domestic infrastructure, you'll often hit a wall at 21 pallets in a 40ft container. Switch to the Euro pallet (1200mm x 800mm), and you can push that number up to 24–25 pallets under the right conditions. For a deeper dive, you can find more details on how these sizes impact shipping container capacity to help with your planning.

Which Pallet Should You Choose?

So, which one is right for you? It all comes down to your shipping route and final destination.

- For Domestic UK Shipments: If your goods are staying within the UK, sticking with the Standard UK Pallet usually makes the most sense. Your supply chain partners, from hauliers to warehouses, are all set up to handle this size as standard.

- For European and International Shipments: If your cargo is heading overseas, the Euro Pallet is almost always the smarter bet. Its dimensions mean a higher pallet count per container, which lowers your cost-per-unit. Plus, it's the standard across the EU, ensuring a smooth handover at the other end.

Ultimately, understanding these two pallet types is the first step in solving the puzzle of how many pallets fit in a 40ft container. By picking the right pallet for the journey, you can stop guessing and start building a precise, optimised load plan that saves both space and money.

Mastering Your Pallet Loading Patterns

Once you've picked your container and pallet type, the real puzzle begins: arranging them to squeeze out every last bit of value. It’s not just a matter of sliding pallets in one after another. A smart loading pattern can be the difference between fitting 20 pallets and 21, and that one extra pallet directly impacts your shipping costs. This is where theory hits the warehouse floor.

The goal is simple. Cover as much of the container floor as you can, making sure the load is stable and secure. Think of it like a game of Tetris. A random approach leaves expensive gaps, but a strategic one creates a solid, interlocking block of cargo.

Whether you're using a UK Standard Pallet or a Euro Pallet often decides which loading patterns will work best, and that directly influences the final answer to "how many pallets fit in a 40ft container?". This is the fundamental choice you're facing.

As you can see, both pallet types are designed to get your goods moving, but their different dimensions call for different strategies to get the best fit and maximise your load.

Straight Loading: The Simplest Approach

The most straightforward method is straight loading. Here, every pallet is loaded with the same orientation, usually with the longer side running down the length of the container. It’s fast, easy for forklift operators to manage, and ideal for uniform cargo.

With Standard UK pallets (1200x1000mm), this typically means placing them two abreast with the 1000mm side facing the door, which fits nicely into the container's 2.35m width. But this simplicity often comes at a price—wasted space. This is why it often gives you a lower pallet count.

Pinwheeling and Turned Loading for Maximum Capacity

To truly get the most out of your floor space, you need to get a bit more creative with patterns like pinwheeling or turned loading. These techniques involve alternating how the pallets are oriented to create a tighter, interlocking layout that minimises empty gaps.

A pinwheel pattern involves turning one pallet 90 degrees to fit snugly against another, creating a square block. This technique is particularly effective for Euro pallets, allowing them to interlock perfectly and fill the container's width more completely.

With Euro pallets (1200x800mm), an alternating pattern is king. Placing three pallets with their 800mm sides across the container width (3 x 800mm = 2400mm) is just a fraction too wide. A much smarter approach is to alternate them: one with the 1200mm side facing the wall, and two with their 800mm sides next to it. This clever arrangement is precisely how you hit the higher counts of 24 or 25 Euro pallets.

For Standard UK pallets, turning a pallet so its 1200mm side runs across the container's width is the key to hitting that 21-pallet benchmark. This allows you to slot pallets into that final bit of space near the doors that a straight-loading pattern would leave empty.

Example Pallet Loading Patterns and Capacities

Seeing how these patterns translate into actual numbers is vital for planning your shipments. The table below breaks down the most common layouts and what you can expect to fit inside a standard 40ft container.

| Pallet Type | Loading Pattern | Description of Pattern | Typical Pallet Count |

|---|---|---|---|

| Standard UK | Straight Loading | All pallets loaded with the 1000mm side facing the door. Simple but less space-efficient. | 20 Pallets |

| Standard UK | Turned Loading | Most pallets are straight-loaded, with the final few turned sideways to fill the remaining space. | 21 Pallets |

| Euro Pallet | Straight Loading | All pallets loaded with the 800mm side facing the door, placed three across. | 23-24 Pallets |

| Euro Pallet | Alternating/Pinwheel | Pallets are turned and interlocked to eliminate gaps, maximising use of the container width. | 24–25 Pallets |

By mastering these loading patterns, you stop just filling a container and start strategically optimising it. Choosing the right pattern for your pallet type is a fundamental skill that directly cuts your freight costs and makes every single shipment more efficient.

Navigating Real-World Loading Constraints

Hitting your theoretical maximum pallet count on paper is one thing. Actually achieving it in a real-world loading bay? That’s a whole different ball game. The gap between a perfect diagram and a safely loaded container comes down to navigating the practical constraints—the non-negotiable factors that eat into your usable space but ensure your cargo arrives in one piece.

The biggest reality check is the payload weight limit. A 40ft container can generally handle a maximum payload of around 26–28 tonnes. If you’re shipping dense, heavy goods like stone tiles or machinery, you’ll almost certainly hit this weight limit long before you run out of floor space.

Think of it like filling a shoebox. Fill it with feathers, and you’ll use every last square inch of volume. Fill it with bricks, and the box will be "full" by weight much faster, leaving plenty of empty space. This is a crucial calculation, because exceeding the payload isn't just inefficient—it's unsafe and illegal.

The Importance of Weight Distribution

Beyond the total payload, even weight distribution is absolutely critical for safe transit. An unbalanced load can make a container dangerously unstable, whether it’s on the back of a lorry, a train, or a ship. It can also put immense structural stress on the container itself.

When loading, you have to spread the weight evenly from front to back and side to side. Piling all the heavy pallets at one end is a recipe for disaster. This often means you can't just follow the most space-efficient loading pattern; you have to use the pattern that creates the safest, most balanced load. A key part of this is ensuring the container itself is on stable ground. To learn more about this foundational step, check out our guide on the essentials of shipping container levelling.

Leaving Room for Dunnage and Securement

A perfectly packed container with zero gaps might seem like the goal, but it’s often impractical. Cargo shifts during transit due to vibrations, braking, and acceleration. To stop this from happening, you need to leave room for dunnage—the materials used to block and brace your cargo.

Common dunnage materials include:

- Airbags: Inflatable bags that are placed in gaps to cushion the load and prevent movement.

- Lumber or wood blocks: Used to create solid barriers that stop pallets from sliding around.

- Straps and lashing: For securing the cargo to anchor points inside the container.

This essential gear takes up space. A few inches for an airbag here and a wooden brace there can sometimes mean sacrificing a pallet position. However, it's a vital trade-off to protect your goods from damage. Beyond just fitting pallets in, it's crucial to understand and follow FMCSA load securement regulations to prevent cargo shifts and damage during transit.

Practical Door Clearance and Forklift Access

Finally, you have to think about the simple practicalities of getting things in and out. A forklift needs room to manoeuvre safely, and you must be able to shut the container doors without crushing the cargo.

It’s standard practice to leave a gap of at least a few inches between the last row of pallets and the container doors. This prevents goods from pressing against the doors, which can make them difficult or dangerous to open at the destination.

This gap between theory and reality is something UK container providers know all too well. Freight operators will often load one or two pallets fewer than the maximum to ensure safe use of equipment like loading ramps and to guarantee door clearance. Factoring in accessories for ventilation or security further refines the realistic pallet capacity of a 40ft unit, turning it from a fixed number into a practical range. Ultimately, these real-world constraints turn the abstract puzzle of "how many pallets in a 40ft container" into a safe, practical, and successful loading plan.

Practical Tips for Safe and Efficient Loading

When you get down to it, the difference between a good shipment and a great one often boils down to the final details of loading. Getting this right means you not only squeeze every last bit of value out of your container's capacity but also make sure your cargo arrives in one piece. These tips will help you pull off a perfect, secure load every time.

First things first: plan ahead. Before you even think about lifting a pallet, calculate the total weight of your shipment. This simple step stops you from accidentally blowing past the container's payload limit—a surprisingly common and expensive mistake, especially with dense goods. A quick weight check can save you a world of logistical pain down the road.

Optimising Your Loading Process

With your weight calculations sorted, it’s time to focus on the physical loading. Nailing your technique is what prevents cargo from shifting around, which is the number one cause of damage during transit.

Here are the key steps for a rock-solid load:

- Inspect Your Container: Before anything goes in, give the container's interior a once-over. Check for damage, make sure it’s clean, and look for any sharp objects that could tear into your goods. A quick sweep can prevent a lot of trouble.

- Load Heavy to Light: Always put your heaviest pallets on the floor and spread them out evenly along the length of the container. If your cargo is stable and stackable, lighter pallets can go on top.

- Keep it Tight and Secure: Pack your pallets as snugly as possible to stop them from jiggling around. Stick to your chosen loading pattern and fill any big gaps with dunnage—think airbags or wooden blocks—to brace the load.

The goal is to create a single, solid block of cargo that moves as one with the container. Even small gaps can let momentum build up at sea or on the road, leading to damaged goods and a dangerous mess to unload.

Using Accessories for Better Security and Space

Beyond basic loading techniques, a few specialised accessories can solve common headaches and add an extra layer of security. If you're using a container for static storage, for instance, installing shelving brackets is a brilliant way to make the most of the vertical space in a High Cube model, keeping your gear organised and easy to grab.

For shipments, especially those travelling through different climates, condensation can be a huge problem. Simple ventilation accessories can help prevent "container rain" and protect anything sensitive to moisture. And if you’re shipping high-value goods, a high-security lockbox is a non-negotiable addition to deter thieves.

Finally, make sure your load is properly strapped down using high-quality straps and anchor points. You can find all the essential lashing equipment for shipping containers you need to ensure every pallet stays exactly where you put it. By combining a solid plan with the right gear, you can master the puzzle of how many pallets fit in a 40ft container and make sure every shipment is both efficient and secure.

Got Questions? We've Got Answers

Planning a container shipment always throws up a few last-minute questions. To help you lock in your loading strategy, here are our answers to the most common queries we get about fitting pallets into a 40ft container.

How Many Pallets Fit in a 40ft High Cube Versus a Standard Container?

This is a great question, but the answer is simpler than you might think. A 40ft high cube container has the exact same floor space as a standard one, so it holds the same number of pallets on the base layer. You're still looking at 21 Standard UK pallets or 24-25 Euro pallets.

The real advantage of a high cube is that extra foot of height. It’s perfect if your goods are unusually tall, or if you’re planning to double-stack pallets—as long as your cargo is stable and you stay under the container's maximum weight limit.

Does Cargo Weight Affect How Many Pallets I Can Load?

Absolutely. In fact, this is probably the single most important real-world constraint you’ll face. Every 40ft container has a maximum payload of around 26-28 tonnes, and you can never, ever exceed it.

If you’re shipping something dense like stone, machinery, or even paper, you might hit this weight limit when the container is only half full. In those scenarios, weight is the deciding factor, not floor space. You must always calculate the total weight of your palletised cargo to ensure you stay within the legal and safe payload capacity.

Key Insight: Always remember, you will likely reach the payload limit before filling the entire cubic space with heavy, stacked goods. Weight is just as important as volume when planning your shipment.

Can I Double Stack Pallets Inside a 40ft Container?

Yes, but it's not as simple as just loading them in. Double stacking is a fantastic strategy for getting the most out of a high cube container's volume, but only if you meet three critical conditions. Safety has to be the top priority.

Before you even think about stacking, make sure you can say yes to all of these:

- Cargo Strength: Your goods have to be strong enough to support the weight of a whole other pallet on top without getting crushed or damaged.

- Pallet Stability: The pallets need to be stable, with the load distributed evenly. If they’re wobbly on the ground, they’ll be a disaster one level up.

- Height Clearance: The total height of two stacked pallets can't exceed the container’s internal height. That’s roughly 2.38m for a standard box and 2.69m for a high cube.

And even if you tick all those boxes, the total payload weight limit is the ultimate rule you must follow.

For all the essential components you need to safely secure, maintain, and customise your shipping containers, trust Quickfit Container Accessories. From high-security lockboxes to durable lashing equipment, we provide reliable, high-quality parts with next-day UK delivery. Explore our full range of container accessories today.