Weight of Container 20ft: A Guide to Tare, Gross, and Payload

A standard 20ft shipping container, when empty, weighs between 1.8 and 2.2 metric tonnes. This figure, known as its tare weight, is the starting point for all logistics planning. It's the baseline for calculating your total shipment mass and absolutely essential for ensuring safe lifting operations. Getting this number right is the first step to managing your container effectively.

Your Quick Reference Guide to 20ft Container Weights

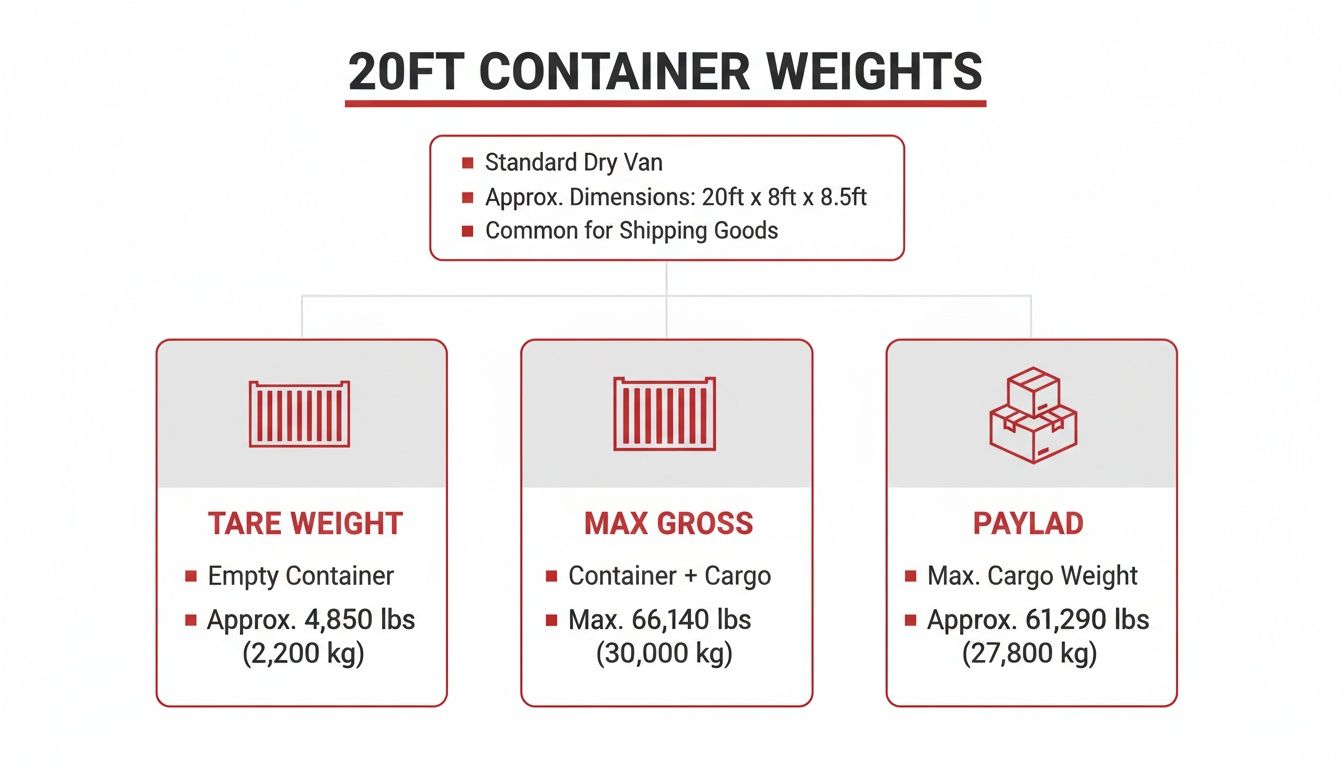

Before we get into the nitty-gritty, it's helpful to have the key figures to hand. The weight of a 20ft container isn't just one number; it's a set of three critical metrics: tare weight, maximum gross weight, and payload. Each one plays a distinct role in logistics, from working out transport costs to making sure you stay on the right side of UK road haulage regulations.

This infographic breaks down these three essential weights at a glance.

As you can see, the image clearly separates the container's empty weight (tare), its maximum possible weight when fully loaded (max gross), and the total weight of the cargo it can actually carry (payload).

Key Weight Definitions

Here’s a quick summary of what those key weights mean for a standard 20ft container.

At-a-Glance 20ft Container Weight Specifications (UK Averages)

This table gives you the typical figures you'll be working with for a standard 20ft dry container. It’s a handy reference for quick calculations.

| Weight Type | Kilograms (kg) | Pounds (lbs) | Metric Tonnes (t) |

|---|---|---|---|

| Tare Weight | 1,800 – 2,200 kg | 3,970 – 4,850 lbs | 1.8 – 2.2 t |

| Max Gross Weight | 24,000 kg | 52,910 lbs | 24.0 t |

| Payload Weight | 21,800 – 22,200 kg | 48,060 – 48,940 lbs | 21.8 – 22.2 t |

Remember, these are average figures. The exact numbers for any specific container will be stamped on its CSC plate, which you should always check.

In the UK shipping industry, the tare weight of a standard 20ft unit typically lands between 1.8 and 2.2 metric tonnes. To be on the safe side, many suppliers suggest using an estimate of 2.2 tonnes, as this accounts for slight variations in construction materials, age, and any repairs the container might have had over its life.

Knowing these figures isn't just about logistics; it’s about safety and compliance. Overloading a container can lead to hefty fines, equipment damage, and serious accidents on site or during transit.

Getting the weights right is fundamental for successful international shipping operations. Of course, weight is only half the story. To get a complete picture, you also need to understand the box's external and internal measurements. We've covered this in our complete guide to the dimensions of a 20-foot shipping container.

Understanding Key Container Weight Terminology

To plan any shipment or site installation properly, you need a firm grasp of the jargon surrounding the weight of a container 20ft. Three core terms define every aspect of loading and transport. Getting them mixed up can lead to costly logistical nightmares, project delays, and even serious safety hazards. Nailing these metrics is the first step towards a smooth, compliant operation.

The main figures you'll come across are Tare Weight, Gross Weight, and Payload. Each one represents a different stage of the container's load capacity and is used for specific calculations throughout the shipping process. Let's break down exactly what each one means.

Defining The Core Metrics

-

Tare Weight: This one's simple – it’s the weight of the container when it's completely empty. This figure includes the steel structure itself, the flooring, and the doors, but absolutely nothing else. A site manager needs this number to pick a crane with the right lifting capacity just to move an empty unit into position.

-

Gross Weight (Max Gross Mass): This is the maximum authorised total weight of the container plus all its cargo. Think of it as a critical safety limit that must never be exceeded. It’s a combination of the Tare Weight and the Payload.

-

Payload (Net Weight): This term refers to the maximum weight of the goods or cargo that can be safely loaded inside the container. You calculate it by subtracting the Tare Weight from the Maximum Gross Weight.

For example, a UK business owner loading pallets of building materials has to know the payload to avoid overloading their container. If a 20ft container has a max gross weight of 24,000 kg and a tare weight of 2,200 kg, the maximum payload they can legally load is 21,800 kg. This foundational knowledge prevents hauliers from refusing the load and saves you from potential fines.

How to Read a Container Safety Convention (CSC) Plate

Every certified shipping container has a small metal panel bolted to its doors that acts as its official passport: the Container Safety Convention (CSC) plate. Think of it as the single source of truth for all the container's weight specifications. Knowing how to read it isn't just good practice; it's essential for anyone responsible for loading or transporting containers. It’s your guarantee the unit meets strict international safety standards.

You’ll usually find the CSC plate fixed to one of the exterior doors, most often the left one. Its whole purpose is to give you immediate, clear, and standardised information about the container's manufacturing details and, critically, its approved weight limits.

Decoding the Weight Information

The plate is stamped with several crucial bits of data, but for your day-to-day weight calculations, you only need to focus on a few specific lines. The details are pressed right into the metal, which helps them stay legible even after years of being battered by harsh weather and rough handling. Understanding this information is also a legal requirement for complying with UK health and safety regulations.

Here’s what a typical CSC plate looks like, so you can see the layout and key data points.

This image clearly shows entries like 'MAX. GROSS' and 'ALLOWABLE STACKING WEIGHT', both of which are absolutely critical for safe loading and transport.

Here are the key entries to look for:

- Maximum Gross Weight: This is the big one. It’s the total permitted weight of the container plus its cargo combined, usually shown in both kilograms (kg) and pounds (lbs). You must never, ever exceed this limit.

- Allowable Stacking Weight: This tells you how much weight can be safely stacked on top of the container. It's a vital figure for port operators and shipping lines where containers are stacked several units high.

- Tare Weight: While it’s not always stamped on the CSC plate itself, you’ll often find the tare weight stencilled on the container door nearby. This number confirms the container's empty weight, which you need to calculate your maximum payload.

By checking these figures directly on the CSC plate, you stop guessing and start working with facts. This simple on-site check means you're using precise, manufacturer-approved data, preventing dangerous overloading and ensuring you're fully compliant.

Weight Specifications for Different 20ft Container Types

When you hear "20ft container," it's easy to assume it's a one-size-fits-all box. But in reality, nothing could be further from the truth. Different container types are engineered for very specific jobs, and these design choices have a direct impact on the weight of a container 20ft. Getting these details right is absolutely critical for choosing the right unit and making sure your cargo can be transported legally and safely.

The main differences come down to construction, which alters the tare weight and, as a result, the maximum payload. A reefer container, for example, needs heavy-duty refrigeration machinery to keep goods frozen, which adds a significant amount of weight before you've even loaded a single pallet. Let's break down the specs for the most common types you'll come across in the UK.

Standard Dry Van Containers

This is the absolute workhorse of the global shipping industry. The standard 20ft dry container, built from tough corten steel, is what most of us picture when we think of a shipping container. It’s designed for pretty much any kind of general-purpose cargo.

- Average Tare Weight: Typically falls between 2,000 kg and 2,400 kg.

- Maximum Gross Weight: Often rated at 24,000 kg, though you'll see some newer models pushing that up to 30,480 kg.

- Typical Payload: This gives you a payload of roughly 21,600 kg to 28,000 kg, but this can vary depending on the specific unit’s rating. Always, always check the CSC plate for the exact figure.

High Cube (HC) Containers

High Cube containers are a fantastic option if you need a bit more vertical space. They give you an extra foot of height, which is perfect for taller goods or just maximising the volume of lighter cargo. That extra height comes from more steel in the structure, which nudges up its empty weight.

- Average Tare Weight: Usually around 2,300 kg to 2,600 kg, so a little heavier than a standard box.

- Maximum Gross Weight: The gross weight rating is generally the same as standard containers, typically 30,480 kg.

- Typical Payload: Because the tare weight is higher, the payload is slightly less, coming in around the 27,880 kg mark.

Refrigerated (Reefer) Containers

Refrigerated containers, or "reefers," are highly specialised units built to move perishable goods at carefully controlled temperatures. They’re packed with features like heavy insulation, special T-section flooring for air circulation, and a big refrigeration unit at one end.

All this extra kit adds up. The refrigeration machinery, dense insulation, and robust flooring mean a reefer's tare weight is considerably higher than a standard dry van's.

- Average Tare Weight: Expect it to be between 2,800 kg and 3,200 kg.

- Maximum Gross Weight: Commonly rated up to 30,480 kg.

- Typical Payload: Thanks to that hefty tare weight, the maximum payload is lower, often around 27,280 kg.

To put this into perspective, let's compare these key figures side-by-side.

Comparison of 20ft Container Type Weights

The table below gives a quick overview of the key weight differences between the standard, high cube, and reefer 20ft container types. It’s a handy reference for seeing exactly how much payload you lose when you opt for a specialised unit like a reefer.

| Container Type | Average Tare Weight (kg) | Max Gross Weight (kg) | Typical Payload (kg) |

|---|---|---|---|

| Standard Dry Van | 2,000 - 2,400 | 24,000 - 30,480 | 21,600 - 28,000 |

| High Cube | 2,300 - 2,600 | 30,480 | 27,880 |

| Refrigerated (Reefer) | 2,800 - 3,200 | 30,480 | 27,280 |

As you can see, while the maximum gross weight is often the same for modern units, the tare weight makes a huge difference to what you can legally and safely load inside.

It's a crucial calculation. UK sea freight data shows a standard 20ft container's empty weight averages 2,400 kg (5,290 lbs). Getting this figure wrong is a costly mistake, as overload fines can hit £500 per incident. This tare allows a net load of 28,080 kg (61,910 lbs) within a 30,500 kg gross limit. However, dense UK exports like machinery often hit this weight cap long before filling the container's internal volume. You can find out more about the complexities of sea freight regulations and how they impact UK businesses.

Factors That Influence a Container's Actual Tare Weight

While the CSC plate gives you the official tare weight for a container 20ft, the reality on the ground is often a little different. For anyone involved in precision logistics, where every single kilogramme matters, understanding what causes these variations is absolutely essential. The stencilled figure is a reliable starting point, but over a container's working life, several practical factors can alter its empty weight.

These seemingly minor discrepancies can have a real impact, affecting everything from payload calculations to transport compliance. It usually comes down to three main culprits.

Manufacturing and Material Differences

Believe it or not, no two containers are created equal, even if they come off the same production line. The manufacturing process itself introduces slight weight differences from the get-go.

- Steel Thickness: Manufacturers might use Corten steel of slightly different gauges, which can easily add or subtract a few kilograms from the final structure.

- Flooring Material: Most containers are fitted with marine-grade plywood floors, but some come with bamboo or even steel alternatives. A steel-floored unit will be noticeably heavier than one with a standard plywood base.

- Paint and Coatings: The thickness and type of paint, along with the protective undercoating, can add a surprising amount of weight, creating minor variances between otherwise identical units.

Age and Environmental Exposure

A container's history and where it's been in the world also play a big part in its current weight. A seasoned unit that’s spent years battling the elements at sea won't weigh the same as a fresh, "one-trip" container.

For instance, the standard plywood floor is porous and will absorb moisture over time, especially in a damp UK climate. This water retention alone can add 50-100 kg or more to the tare weight – a factor that’s frequently overlooked in payload calculations. This is particularly important if you're thinking about modifications, and you can learn more in our guide to effective shipping container insulation.

Repairs and Modifications

Finally, any repairs or customisations will inevitably change a container's original tare weight. Every patch welded onto a damaged wall, every reinforced floor fitted for heavy machinery, and every lockbox or shelving bracket added contributes to the overall mass. These additions might seem small, but they all add up.

Navigating UK Road Haulage Weight Regulations

Knowing the maximum gross weight of a 20ft container is only half the battle. You also have to navigate the UK's strict road transport laws, and this is where many people get caught out. The figures on the CSC plate tell you what the container can physically handle, but it’s the Driver and Vehicle Standards Agency (DVSA) that dictates what’s legal to move on public roads.

Getting this distinction wrong is a recipe for hefty fines, frustrating project delays, and serious safety risks.

The golden rule is simple: the total combined weight of the vehicle, trailer, container, and cargo must not exceed the legal road limit. For a standard six-axle articulated lorry in the UK, that limit is typically 44 tonnes (44,000 kg). This figure is non-negotiable and always overrides the container's own maximum gross weight rating when you're planning road transport.

Calculating Your True Maximum Payload

This is where the theory meets the real world of logistics planning. Even if your 20ft container is rated for a 28-tonne payload, you can't just load it to the brim and stick it on a lorry. You have to account for the weight of everything else.

A typical calculation looks something like this:

- Articulated Lorry Tare Weight: Roughly 15,000 kg (this includes the tractor unit and the skeletal trailer).

- Container Tare Weight: Around 2,200 kg.

- Total Empty Weight: 15,000 kg + 2,200 kg = 17,200 kg.

With a 44,000 kg road limit, this means your actual maximum legal payload is 26,800 kg (44,000 kg minus the 17,200 kg empty weight). It's a fair bit less than the 28,000 kg or more the container might be rated for.

Understanding the precise weight of a 20ft container is crucial for effective load planning and preventing HGV overloading, which can lead to significant penalties and safety risks.

Forgetting to run this simple calculation is a common and expensive mistake. If your container is overweight, hauliers will flat-out refuse to transport it, leaving you with wasted time and money at the collection point. For specialist on-site moves, you might need to look at different solutions altogether. For instance, our guide on fitting a shipping container tow bar explores other options for shifting containers around a site without a lorry.

Your 20ft Container Weight Questions Answered

When you're dealing with shipping containers, a lot of questions come up around weight. It’s a critical factor for everything from safety to cost. To give you some quick, practical answers, we've tackled the most common queries we hear.

Think of this as your go-to reference for sorting out the specifics. We’re cutting through the jargon to give you the information you need to handle your logistics with confidence.

How Can I Find The Exact Tare Weight Of My Container?

The most straightforward way is to check the container doors. The Tare Weight is stencilled right on there, usually close to the CSC plate. This figure tells you what the container weighs completely empty.

However, for absolute certainty—especially with older units or containers that have been modified—the only foolproof method is to get it weighed at a certified weighbridge. This provides a documented weight certificate, which is incredibly useful for precise cargo planning and staying on the right side of legal requirements.

Does a Container's Weight Really Affect Shipping Costs?

Yes, absolutely. A container's gross weight is one of the biggest factors that determines your shipping bill. Heavier containers mean more fuel burned during transport and require more powerful equipment for handling at ports and depots.

Shipping lines typically charge on a 'weight-or-measure' basis, meaning they'll bill you for whichever is greater—the volume or the weight. If you're shipping dense, heavy cargo in a 20ft container, you can bet that the total gross weight will be what your freight charges are based on.

What's The Safe Stacking Limit For A Loaded 20ft Container?

You'll find the safe stacking limit listed on the CSC plate under 'Allowable Stacking Weight'. This number, often around 192,000 kg (423,280 lbs), is the maximum weight that can be loaded on top of the container when it's at the bottom of a stack.

It’s a crucial safety figure for both port operations and life on a container vessel, where containers can be stacked up to nine high. Exceeding this limit jeopardises the container's structural integrity and could lead to a catastrophic collapse.

A common point of confusion is thinking this limit applies to the container's own gross weight. It doesn't. It only refers to the total combined weight of all the containers stacked directly above it. Always check the CSC plate for the official value.

Can I Load Heavy Items Anywhere Inside The Container?

No, you can't. Even if your total cargo weight is well under the maximum payload, you have to distribute it as evenly as possible across the container floor.

Concentrating a heavy load in one small spot can damage the flooring, create dangerous imbalances during lifting, and make the entire unit unstable for transport. Proper load planning means spreading the weight out to keep the container's centre of gravity where it should be. A well-balanced container is a safe container.

For all your container maintenance and customisation needs, from high-security lockboxes to shelving and ventilation, visit Quickfit Container Accessories. Explore our extensive online catalogue for next-day UK delivery on hundreds of essential parts. https://www.quickfitcontaineraccessories.co.uk